Bioengineering Undergrads Build Biobots in New BIOE 306 Course

December 16, 2015

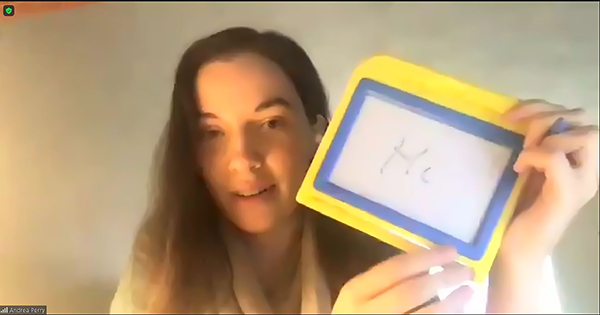

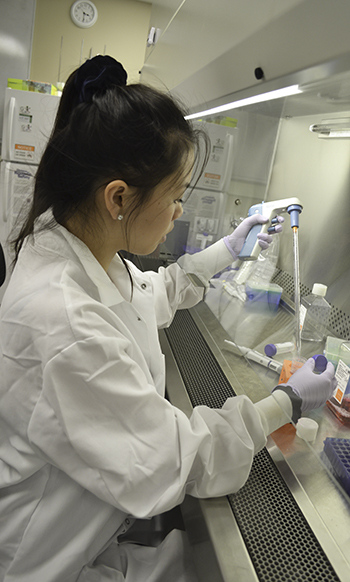

An Illinois Bioengineering undergrad, Anna Whelan, performs research inside a biosafety hood during one of BIOE 306's labs.

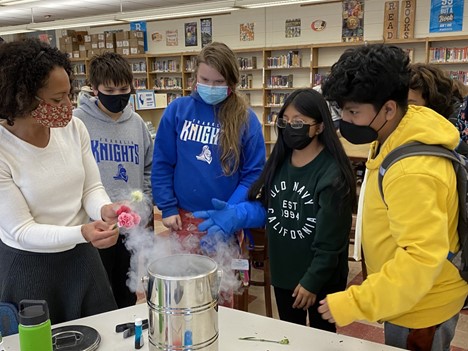

Biobots. The word smacks of scientific breakthroughs in the distant future, or the subject matter of some futuristic, sci-fi movie. But Illinois researchers are currently building and studying biobots as part of their research in this emerging field. However, they're not the only ones. This past semester, Illinois' Bioengineering department piloted a brand new course, BIOE 306, BioFabrication Lab, that teaches undergraduate students how to build them too. Developed as part of the NSF-funded EBICS (Emergent Behaviors of Integrated Cellular Systems) Science and Technology Center, the course distilled down cutting-edge EBICS research and initiated eight Bioengineering juniors and seniors into the mysteries of building with biology. In addition, the idea for this class was developed in part due to the Illinois Innovation Prize, which emphasized the need to teach the next generation of engineers and scientists how to "build with biology."

The class was a Bioengineering team effort, with several folks helping to develop and teach the course and labs: Rashid Bashir, Head of Illinois' Bioengineering department and EBICS Associate Director, Bioengineering Assistant Professor Pablo Perez-Pinera, who primarily taught the class; Ritu Raman, the EBICS researcher and NSF Graduate Research Fellow who helped design and co-lecture the class; and Colin Castleberry, the teaching assistant for the course.

According to Raman, Mechanical Engineering Ph.D. student: “The idea is basically that we design and build our own bio-integrated machines that are powered by muscle. The goal of this class is basically to expand that expertise beyond just EBICS researchers, and teach undergrad Bioengineering students the skills they’ll need to build with biology.”

“I think this is a great example of how cutting-edge research funded by an NSF center can be disseminated to undergraduate education,” adds Bashir.

So exactly what is a bio-integrated machine, or biobot? As its name suggests, it’s part biological, part robot. Raman clarifies, “A broad definition of biobot would be anything that’s harnessing a biological tissue to do a non-natural function.”

So is a biobot comprised completely of organic, or biological, material? She says no.

A Bioengineering undergrad, Audra Storm, works with the biobots she made as a final project for BIOE 306.

“Basically it’s bio integrated or a bio hybrid. So it’s powered by biological tissue, like muscle, but it’s coupled with a skeleton that’s made out of non-biological materials.”

Raman elaborates: “A robot is something that can send some sort of signal, do some kind of internal processing, then respond to it in a certain way. A biobot is a robot that has some kind of biological tissue that’s either doing the sensing, processing or actuation, or whatever.”

How large are biobots? Much larger than nanoscale, they’re at the millimeter scale. They’re larger than cells, since living cells are used to power them.

What’s the energy source for biobots? Like with plants (and people), it’s sugar. The light is the trigger which sends an electrical signal to the muscle and the muscle uses sugar in the surrounding media as energy.

“We all need food.” Bashir interjects.

“It seems really obvious because you learn those things in biology,” explains Raman, “but there are times when I’ve bought a new media that didn’t have glucose in it. I thought, ‘Why aren’t these biobots twitching?’ That bothered me for a week until I realized there was no sugar. You need to remember these basic things.”

An Illinois Bioengineering undergrad, Alexandra Palasz, works with the biobots she and her teammate created during the BIOE 306 course.

So why study and build biobots? According to Bashir, they could be used for drug screening, such as gauging the effect of different drugs on the human body based on the response of organs or cells. Another use would be autonomous sensing and release devices to regulate toxins in the environment. For instance, biobots could be used to sense a chemical and release something to neutralize that agent.

“There’s many applications like that,” Bashir explains, “but our vision is broader in many ways.”

In fact, he says that’s just the tip of the iceberg in terms of biobots’ potential. He says the course was designed to prepare students for what he terms “forward engineering with biology.” For instance, according to Bashir: “Someday, anything that you see that’s built out of non-biological material today could be built with biology in the future.”

To give students plenty of hands-on opportunities with biobots, in addition to lectures, the course was comprised of five labs. Four taught students skills they’d need to design and build them; the 5th was like an independent project, where students designed and built their own biobot.

Bioengineering Assistant Professor Pablo Perez-Pinera, whose work is in the area using mammalian cells in synthetic biology, is the BIOE 306 instructor.

He explains why the lab component is so important:

Bioengineering Assistant Professor Pablo Perez-Pinera shows research done in BIOE 306.

“Lectures are not the only way of teaching efficiently. From what I recall, when I was a student myself, I often learned more efficiently from going to a lab every week, because then you see the connection with what you’re being taught in the lectures and how everything works in real life. That’s why I like the idea of using labs to support the lectures. In class, I speak of lentiviruses for gene delivery, and it may sound complex or even dangerous or scary, but then we go to a lab, learn how they function and how to use them safely and, at that point, the students understand that they are easy to build and highly efficient. It gives them a different perspective of things, and I think the students really benefit from it.”

Apparently Perez-Pinera and Bashir are on the same page when it comes to undergrads being involved in important research.

"Rashid and I think undergrads are fully capable of doing cutting-edge research if trained properly. So the question we asked is, ‘Why not?’ Why can’t undergraduate students make lentiviruses or biobots? At the end of the day, it comes down to a set of instructions that they have to follow.'"

To take the course, students must have had prior instruction in cell culture. “What that means is they know how to work inside a hood in a sterile way so that they don’t kill cells,” explains Raman. “Everything else we teach you.”

BIOE 306 teaching assistant, Colin Castleberry chats with students during a BIOE 306 lab.

Raman says the first lab is pretty basic: to make sure students “know how to grow up cells and not kill them,” she says in an aside. She explains that 3D printing of biobots uses photo initiators, and of those available, one is good for cells; the rest are toxic. The students learned to test the effect of these different photo initiators to determine which is “the one that’s not going to kill all the cells,” explains Raman. “That’s the one they’re going to use.”

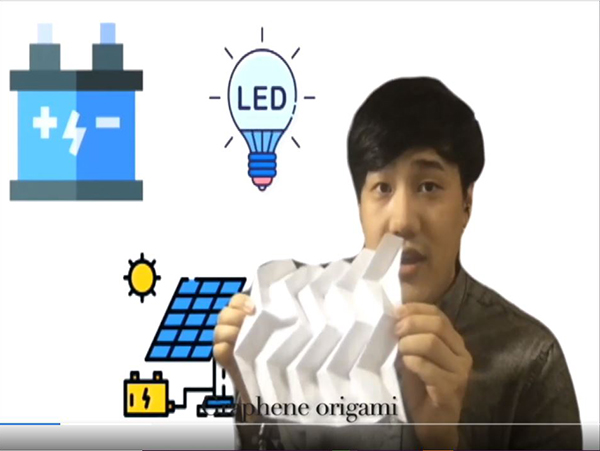

In the next lab, students made optogenetic cells. Muscle cells used to create the biobots are optogenetic. “They respond to light,” explains Perez-Pinera. “The biobot should be walking when you shine blue light.” Researchers can get biobots to do things by flashing light on them to make the muscle contract. So in this lab, students were given a regular muscle cell line then taught how to create their own optogenetic cell line which they would use for future experiments.

In the third lab students learned about 3D micro environments.

"We’re taking cells that we grow on a 2D plate, and trying to build a muscle in a 3 dimensional culture and controlling the behavior of those cells so that they contract on command," says Perez-Pinera.

In this course, students learned to seed cells in hydrogel to see how cells interact in 3D and remodel their environment—which they needed to understand before they could make a 3D muscle.

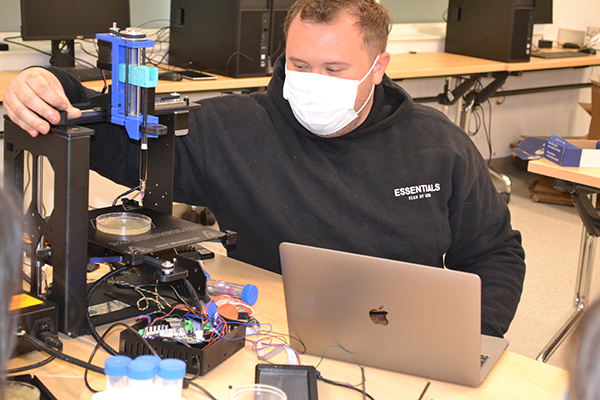

Next, students learned how to 3D print. They designed a 3D model in CAD, then 3D printed it themselves. While 3D printing is often done with polymers, they learned to do it with biocompatible biomaterials (similar to what’s used in contact lenses). Cells can grow on and in them.

In the fourth lab, students replicated a biobot design, trained it, flashed light on it, then got the results. This data analysis is where some of Ritu’s research came into play. She taught students to “look at how much the biobots are moving, and use mechanical modeling to extract data, so we know how much power is being output by this muscle.”

“So that’s fun,” Raman says of the fourth lab, “and they learn how to make a biobot. But that’s not exciting, because they just made a biobot that I already make!” So for the pièce de résistance, they had students design their own biobots.

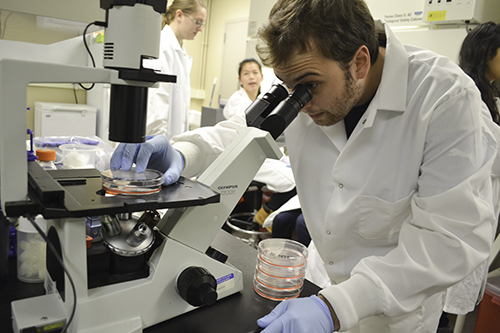

TechServices VPN

TechServices VPNDuring a lab, Bioengineering undergrad, Erik Anderson, examines biobots he created under a microscope.

Perez-Pinera claims having students do their own project the last 3–4 weeks of class is something that worked out well in in his last class, so he thought it would be a good idea to do the same in this class. He tells the students: “Take what you have learned and do yourself a project…I’m supporting you, and I’m here to help, but it’s going to be your idea and your project. It’s all up to you—how creative you are. “

Perez-Pinera says the first 2/3 of the class they’re going to be building very simple biobots, so the final project gives students a chance to be creative. “So we’re hoping that they’ll be able to do design something more complex. It would be interesting,” he admits.

“And I’m hoping that they come up with ideas that we haven’t thought of before,” adds Ritu.

Ritu adds that for their final project, they would screen them to ensure that everyone’s ideas were different, but also feasible. “And then they kind of just go rogue and make that thing!” she finishes.

For the final event of the course, students presented their projects to Professor Bashir and other EBICS faculty. In addition, they held a group discussion on ethics “A big focus of the center is responsible bioengineering,” acknowledges Raman.

Bashir says that ethics training is extremely important, especially in an emerging field:

Left to right: Rashid Bashir, Head of the Department of Bioengineering and EBICS Associate Director, and Mechanical Engineering Ph.D. student and EBICS NSF Graduate Research Fellow Ritu Raman.

“So we have to be very careful with that,” adds Bashir. “Any new technology people can hopefully use it for helpful things, but you can think about how it could be used for not-so-helpful things. So our goal is to make sure that we keep bringing that up, and have people think about and discuss how this technology could be used and discuss ethical implications of this work.”

In fact, EBICS had already developed and piloted a biobots ethics module last summer, which he says will be used as a starting point for the discussion.

“When you are dealing with building biological structures, the question of ‘How close is this to living entities?’ and ‘What are the ethical implications of that?’ are approached. We already have a couple EBICS ethics modules. We are going to use them as a vehicle to get students started on the discussion and to discuss other things that they have on their minds and be able to talk about how to manage those concerns.”

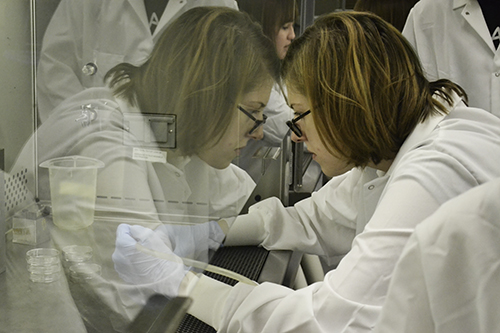

Left to right: Michael Gapinske and Lauren Grant work on their final project during a BIOE 306 lab, which Perez-Pinera calls, " spectacular."

Bashir elaborates on why the ethics component is so important: “The idea is, ‘How do you let people be creative but yet put some measures that protect and prevent people from going too rogue?’ We also have to be careful about how to present that to the general public…it’s very important how you present it in the context of being responsible about this research in terms of how it could be used.”

While the hope in developing this course is that some of these undergrads end up in this field of research, Bashir says their purpose more broadly is to take the research and disseminate to undergrads.

“So our purpose here was to try to get the research integrated with education and knowledge transfer and disseminated at the undergraduate level to get people to think about more of such applications.”

He explains that EBICS’s goal is to actually go beyond tissue engineering, to not just build organs but rather “hyper organs” or try to do non-natural functions and build such kind of machines, biological soft robots or “biobots.”

“The focus is more on going past the tissue engineering applications, but through this course, we want to impart the skill sets to the students to either go into tissue engineering or be thinking about this idea of 'forward engineering with biology.'”

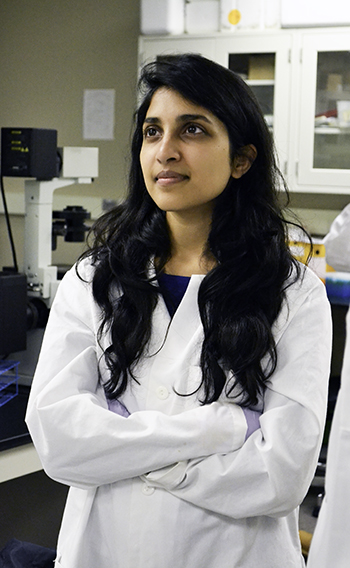

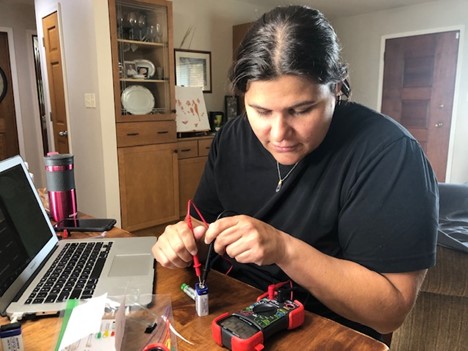

Ritu Raman, who helped develop the BIOE 306 course.

Bashir also indicates that the course provided a great opportunity for Ritu to take on a leadership role.

“It’s an EBICS brainchild; we talked about wanting to do this, and she really made it happen,” explains Bashir.

One look at Raman‘s expertise explains why her participation in the course is key. Her emphasis involves higher resolution in 3D bio printing. For the past three years she’s been developing the enabling technology: modifying a commercial 3D printer and building a separate apparatus that prints at a much higher resolution. Her other emphasis? Building different types of biological machines.

“Expanding the functionalities that we can have with biological machines. It’s been really helpful for me to have a project that’s been very focused on a tool that can be used for many different things, and then a project like biobots, which is what I would consider a specific application or focus area for that tool.”

Raman believes another important goal of the course is to develop a baseline bioengineering curriculum:

“Because Bioengineering undergrad curriculums, in general, are so new, a lot of people don’t really know what a bioengineering undergrad degree is. So…we’re saying, ‘These are the tools that a bioengineering undergraduate student has. That’s something that people from mechanical, or chemical, or material science don’t have. This is the expertise that a Bioengineering person has…something unique that you’ll only get with a bioengineering degree.”

“This is something that should be taught,” agrees Bashir. “Again, this space of fabrication and 3D printing is moving very rapidly. There’s lots of applications in the space of bio engineering. It also provides a tool to do this forward engineering with biology. So, yes, we think that this should be an important part of undergrad curriculum.”

What are the plans for the course in the future? While it might eventually be disseminated for use by other institutions, especially EBICS’ partners, Bashir says the idea was to pilot it on a small scale to work out all of the bugs, with the goal of launching it fall 2016.

“I think we’re going to start here with this course, and do a good, high-quality job at it, and scale it up locally here,” qualifies Bashir.

Raman adds that it could also be disseminated as, say, a three-week lab module that could be incorporated into existing tissue engineering or bioreactor courses.

Based on this course and related discussions around building with biology, Bashir says that Bioengineering is considering instituting a new synthetic biology track, and this course might be part of that.

“Building with biology is very unique to bio engineering,” says Bashir. “So we're actually thinking of adding more courses…at the undergrad level and create a formal track."

Story and photographs by Elizabeth Innes, Communications Specialist, I-STEM Education Initiative.

For more related stories, see: BioE, EBICS, Funded, Undergrad, Undergrad Ed Reform, 2015

BIOE 306 students Howard Dabbous and Alexandra Palasz look on as Ritu Raman (right) works with the biobots they created.

.jpg)