MechSE Seniors Seek to Make Congenital Amputee’s Dream of Operating Cat Heavy Equipment a Reality

Dylan Taylor at Duininck, checking out the big Cat equipment. (Image courtesy of Dylan Taylor.)

Dylan Taylor at Duininck, checking out the big Cat equipment. (Image courtesy of Dylan Taylor.)

June 11, 2020

Ever since he was a boy, Dylan Taylor has envisioned a career behind the controls of some really big construction equipment. Now that he’s 18, he still dreams of operating some of the big boys—specifically, Caterpillar’s excavator, bulldozer, and motor grader. However, to achieve this dream, Taylor must first overcome a significant conundrum. Born with a congenital defect, he’s missing his left hand, and most of Cat’s equipment is maneuvered via dual joysticks. So a team of five Mechanical Science and Engineering (MechSE) seniors, in collaboration with Caterpillar, were excited to help Taylor achieve his dream. For their ME 470 senior capstone design project, the soon-to-be-engineers designed several machine control adaptations, which, before too long, will help to make Taylor’s dream a reality.

“As a child, I was always intrigued by heavy equipment,” admits Dylan Taylor. “I loved riding with my dad in his backhoe.” He recalls how they would dig down to buried sewer pipes to fix them as part of his dad’s plumbing business. Recently hired by Duininck, a Minnesota construction company, Taylor currently isn’t an equipment operator. “Running heavy equipment is something I have to work my way up to…” he admits, “but eventually I will get an opportunity in the seat of a machine.”

However, before he can find himself in the seat of one of Cat’s machines, he needs to be able to interface with their equipment, especially the dual joysticks. So Taylor was proactive; he contacted Caterpillar about his passion…and his dilemma. Enter ME 470’s Team 36, comprised of five MechSE seniors, Steven Harris, Isaac Husemann, Moira Iten, Clark Mitchell, and Morgan Sutherland. Brought into the loop as part of Caterpillar’s partnership with Illinois Engineering, the team was eager to tackle the machine control adaptations Taylor needed.

According to Isaac Husemann, the Senior Design course aimed to “use all of the engineering, collaboration, and problem-solving skills we’ve developed throughout our four years at UIUC.” He adds that “Senior Design is especially interesting because each group has a completely different project, with unique deliverables and requirements, and are real-world projects aimed at helping companies or organizations develop a new project.”

Dylan Taylor seated in a Caterpillar Excavator during his and Team 36's visit to the plant in Peoria. (Image courtesy of Team 36's final presentation.)

Dylan Taylor seated in a Caterpillar Excavator during his and Team 36's visit to the plant in Peoria. (Image courtesy of Team 36's final presentation.)

But what Husemann found particularly rewarding was that, rather than developing a project to help a company per se, which was what most ME 470 groups did, their project was unique in that they had an opportunity to actually help an individual. “We had an especially empathetic and specific project that could truly change Dylan’s life,” he explains.

Another member of the team, MechSE senior Morgan Sutherland would agree: "The most rewarding part of the project was interacting with Dylan," she admits. " Dylan is an inspiring person, and I feel grateful to have been able to work on this project to benefit him. Being able to be a part of such a meaningful project and to impact someone's life so directly was amazing."

Dylan Taylor says he was honored to be given the opportunity to work together with the students and the team from Caterpillar. Calling it a “once-in-a-lifetime experience," he continues, “Me being only a senior and being given the opportunity is astonishing and rare, as how I see it. I bet not many high school or college students have even set foot on Caterpillar's proving grounds. I'm beyond thankful for this opportunity.”

To begin, the team settled on three major project design specifications: Taylor should be able to put each apparatus on by himself; also, the designs should be able to effectively and safely control the machines, and should take into consideration the operator’s environment (dirt, dust, humidity, changing temperature, etc.). In addition, from among a long list of design concepts, including performance, size and weight, and quality and reliability, the team decided these three concepts were of the highest priority: end-user opinion, safety, and ease of use.

To develop their designs, the students used the 4D Design Thinking approach. This philosophy breaks the design process down into four stages:

- Discovery (involves empathizing with the client to understand his/her needs and abilities);

- Definition (development of a problem statement and drafting of product design specifications);

- Development (prototyping, materials research, and iteration of design); and finally,

- Delivery of four designs and one prototype at the end of the project.

Isaac Husemann (seated right) and other members of Team 36 take measurements in order to ensure that Dylan Taylor (seated left) gets a comfortably-fitting apparatus. (Photo courtesy of Isaac Husemann.)

Isaac Husemann (seated right) and other members of Team 36 take measurements in order to ensure that Dylan Taylor (seated left) gets a comfortably-fitting apparatus. (Photo courtesy of Isaac Husemann.)

Once they’d come up with some initial designs, the team met Dylan Taylor in Peoria at the Caterpillar plant to discuss his needs, present their designs, and see some of Cat’s construction equipment up close.

Regarding this initial meeting, MechSE Teaching Associate Professor Leon Liebenberg, who teaches ME 470, shares that Taylor was “not the average customer. He is technically proficient on many levels, not just at operating a series of heavy equipment. He also produced several technical sketches showing his ideas, i.e., he shared with us his needs and his wants via his drawings, and also with the team meeting him two months ago.”

Husemann recalls, "That morning we presented the initial design ideas we had come up with and then Dylan presented the sketches he had. Interestingly, our ideas were pretty similar to Dylan's, which was a good confirmation that the ideas we had come up with were feasible and also something that Dylan would actually like to use.”

The design suggestions Taylor gave the students were ideas he had thought through for several months. He reports visiting Duininck's shop last summer to take pictures and measure the controls/joysticks of machines parked there.

“After getting those measurements, I would go home and sketch out the joystick and start brainstorming some ideas and thoughts,” he recalls. In fact, some of the questions he asked himself, such as "‘Could this attachment be versatile?’ ‘What kind of comfort would I have with this idea?’ ‘Is this safe?’ and so forth” were some of the same questions Team 36 had asked themselves when designing the project.

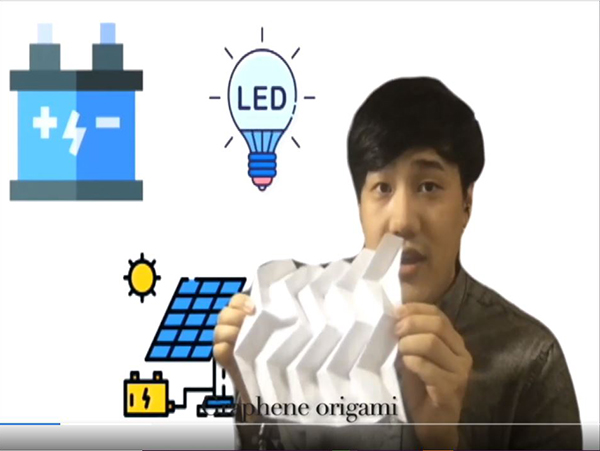

Here are brief descriptions of their designs. The Excavator adaptor (to the left) consists of a moulded armrest with a miniature drawer slide that enables it to slide forward and backward; mounted atop is a rotary shaft which pivots on a bearing. This combination of linear slide and rotation would enable Dylan to control all four degrees of freedom required for the excavator. A 3D-printed arm connector moulded to the shape of his stump would allow comfortable and secure control of the excavator. Finally, a ball joint connects to a clasp, securely attached to the joystick.

Their dozer apparatus consists of a custom-fit apparatus mounted directly to Taylor’s stump; a 3D-printed clasp attaches to the joystick via a hinge and toggle clasp at the end of angled 3D-printed telescopic tubing. Bolted to the apparatus, it allows Dylan to adjust the length of the arm attachment. The end of the tubing is bent at a 20˚ angle to align with the joystick's position..

After creating prototypes for both of the above, they corrected several design issues in second iterations. However, in the midst of their design process, they learned that their designs must comply with FDA (Food and Drug Administration) specifications, requiring them to make universal designs in addition to their original designs, in order to comply with prosthetic device laws.

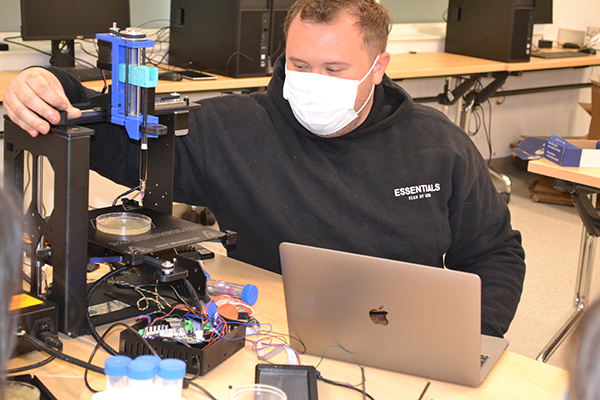

MechSE senior Isaac Husemann. (Image courtesy of Isaac Husemann.)

MechSE senior Isaac Husemann. (Image courtesy of Isaac Husemann.) The most challenging part of the project for Sutherland, was applying their knowledge of mechanical engineering to a new field. The prosthetics and medical device industry is not one that we are exposed to in our curriculum alone," she admits. "There was a lot of learning and research that had to be done throughout the entire semester to make sure we were addressing the problem in the best possible way for Dylan."

And then, in what was probably an even bigger hurdle, the COVID-19 pandemic struck, causing a major upheaval in the traditional way of doing things—specifically, no more face-to-face communication, no access to Illinois’ fabrication equipment, and no further meetings with the clients to test their designs. Husemann reports: “The sudden change in resources and overhauled deliverables was more overwhelming. Luckily, we had just finished our initial prototypes of our designs just a few days before spring break, which were incredibly useful in finding adjustments to make to our designs.”

According to Husemann, the COVID-19-related lockdown caused several changes to the status quo. He says his team quickly adapted to the increased telecommunication, indicating this is similar to how many companies operate normally. They conducted Zoom calls four times a week, increased messaging through Slack, and began organizing/storing all files on Google Drive and Box.

"Despite all the challenges we faced," Sutherland confirms, "our team continued to have strong communication throughout the semester. After spring break, we continued to meet four times throughout each week, and we devoted as much time as we could to iron out any possible issues in our designs. Our main goal for this project was not the grade, but rather to impact Dylan's life the best way we could.

MechSE senior Morgan Sutherland. (Image courtesy of Morgan Sutherland.)

MechSE senior Morgan Sutherland. (Image courtesy of Morgan Sutherland.)However, a change they found more difficult, according to Husemann, was that they didn’t have access to tools they’d gotten used to during their time at Illinois, such as 3D printers and laser cutters. “Most importantly,” he continues, “we lost the ability to meet together and discuss our designs, work through product assembly, and really get to see how our client will physically interact with our design.” Despite their inability to continue to iterate their designs and assemble new prototypes in person, he claims, “We managed to create incredible designs that, once prototyped and tested, should work well and help Dylan start his career.”

Because of the COVID-19 lockdown, the team was unable to meet face to face with Dylan again after their initial meetings. "The hardest thing about the COVID-19 disruption was losing the ability to have face-to-face interaction, both as a team and with Dylan," Sutherland admits. "We had hoped to show our initial prototypes to Dylan in person to get his feedback, and continue to test and build final prototypes together. Unfortunately, neither of those things were able to happen and our designs had to remain digital."

So, in lieu of face to face, near the end of the semester, they had a Zoom meeting with him, during which they presented their Excavator and Dozer designs, electronic designs for accessing the dozer, and initial motor grader designs.

Regarding this opportunity to talk with Dylan through Zoom, and show him their final designs, Husemann admits: “Seeing him get so excited about the designs and interested in the materials and functionality of the devices was so rewarding. I really can’t wait to see these designs come to fruition (hopefully in the near future!) so Dylan can start his career.”

Members of Team 36 and Dylan Taylor get a tour at the Caterpillar plant in Peoria. (Photo courtesy of Team 36's final presentation.)

Members of Team 36 and Dylan Taylor get a tour at the Caterpillar plant in Peoria. (Photo courtesy of Team 36's final presentation.)

However, since his team was unable to build prototypes of their designs or meet with Taylor to test the prototypes developed, and since they will all be graduating this May, they’ll be passing the baton to others who will prototype, test, and possibly tweak their designs.

“If all of the design works as intended,” says Husemann, “ideally all that would be required of another group is to make any minor design tweaks to ensure the devices work as best as possible.” However, the soon-to-be-engineer shares that if there’s one thing he’s learned about his field, which he claims is typical with product development, it’s this: “CAD designs rarely work 100% as expected. So, some further iterations and prototyping will likely be required to get the best device possible for Dylan.”

While Husemann and his team were definitely invested in the project, he is hopeful that the project is completed, even if it’s not by his team. He just wants to see it finished and making a difference for Dylan.

“This project is much larger than just our team,” he says. “The successful development of these devices will help Dylan be able to operate machinery.”

Morgan Sutherland (center) practices applying a mould to a teammate's elbow prior to making a mould of Dylan's stump. (Image courtesy of Morgan Sutherland.)

Morgan Sutherland (center) practices applying a mould to a teammate's elbow prior to making a mould of Dylan's stump. (Image courtesy of Morgan Sutherland.)Wishing they could have "finished" the project themselves, Morgan Sutherland nevertheless believes they left the project in good shape. "It is disappointing that we won't be able to personally see this project through to the end, but I think we have done a lot of great work for this project. We delivered detailed designs that should allow the next group to pick up the project easily."

However, she acknowledges that the most important thing was helping their client. "The most important thing is that the project will still be completed, and Dylan will get a final product that will allow him to have the career he wants."

Regarding Dylan Taylor’s take on the process, he claims, “Working with the team has been amazing and such an awesome experience! I was not only very impressed by the student's advanced thinking, but also their tenacity to keep developing ideas and figure out a working prototype within a set amount of time.”

Dylan Taylor by a Cat Excavator at Duininck, a Minnesota construction company. (Image courtesy of Dylan Taylor.)

Dylan Taylor by a Cat Excavator at Duininck, a Minnesota construction company. (Image courtesy of Dylan Taylor.)

Taylor then waxes philosophical about the entire experience: “I truly believe teamwork can get you pretty much anywhere. Coming into this project, I wasn't sure how much we could really do or create, but if you put together the right minds, the possibilities are far greater than working solo!”

About the entire process, Liebenberg adds: "It was an absolute pleasure to produce something that will help Dylan in real life.”

Story by Elizabeth Innes, Communications Specialist, I-STEM Education Initiative. Photographs by Elizabeth Innes unless otherwise noted.

Other I-STEM articles about MechSE courses:

- From Trash to Treasure: Liebenberg Uses Design for Repurposing to Spark Student Interest in Online Classes, Possibly Making a Difference in the COVID-19 Pandemic

- Via ENGINE, a Group of Illinois Educators Promote Using Playful Pedagogies to Engage Students

- Liebenberg’s ME 270 End-of-Semester Main Project Presentations Showcase Students’ Manufacturability Redesigns

- ME370’s Final Competition—March of the Automata—Fosters MechSE Students’ Creativity, Perseverance, and Teamwork

More: Student Spotlight, MechSE, 2020

Team 36 and Dylan Taylor see some of Caterpillar's big machines up close at its Peoria plant. (Image courtesy of Team 36's final presentation.)

.jpg)