BIOE435 Capstone Projects—BIOE Seniors Use Knowledge/Skills to Problem Solve

May 12, 2021

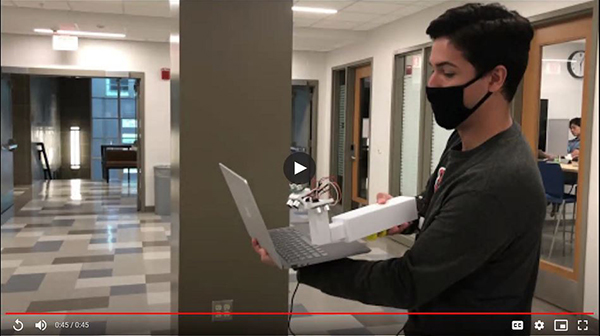

Preston Njapa Njeuha presents his team's design: a Prosthetic Robotic Hand.U

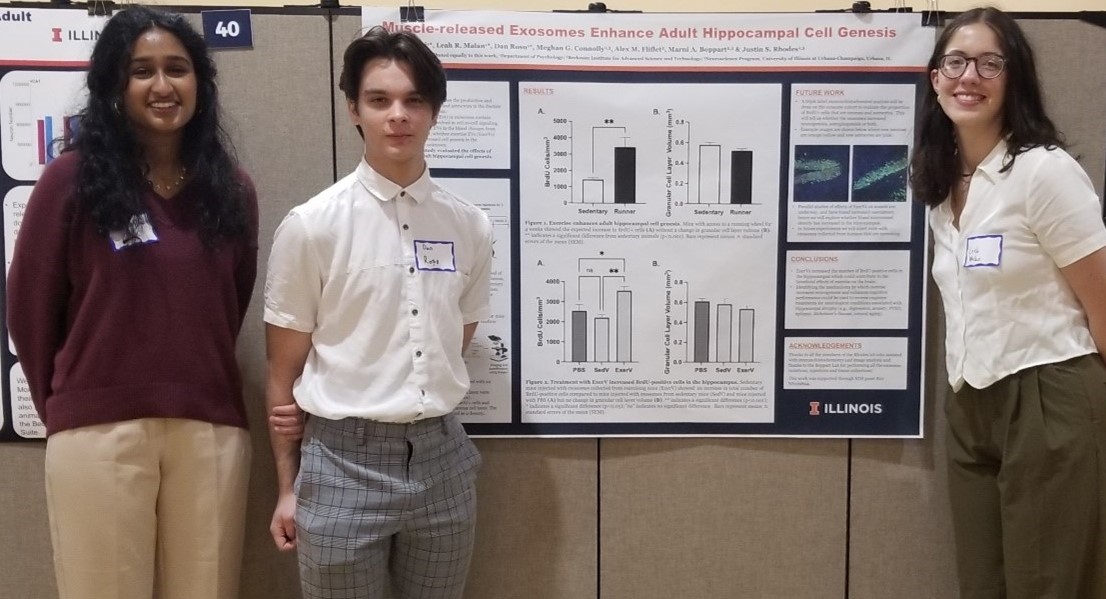

There comes a point in a Bioengineering (BIOE) student’s career at Illinois when they get to demonstrate all the knowledge and skills they’ve acquired, in combination with their creativity and acuity in problem-solving, to come up with a viable solution to a real-world problem. Assistant Professor Holly Golecki’s BIOE 435 Senior Capstone Projects course is one such pivotal point for BIOE seniors—it’s a final chance to prove themselves prior to entering the real world as engineers. Thus, for the students, as well as their professor, the most exciting event of the Spring 21 semester was finally getting to present their completed projects at the May 4th BIOE Senior Design Virtual Symposium—something they’d worked toward for not just a semester—but their entire four years at Illinois, actually.

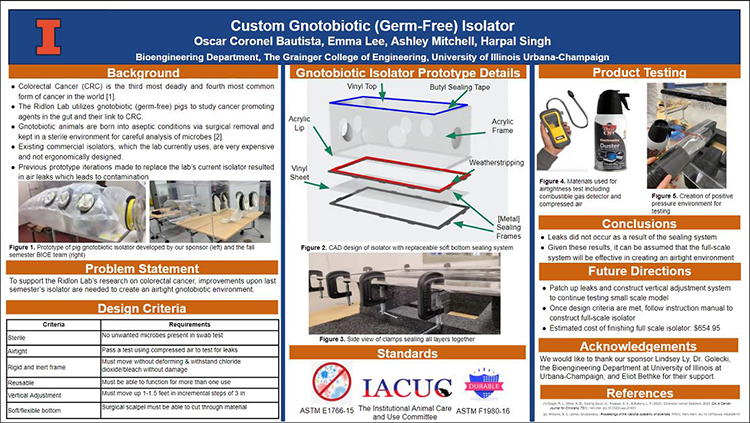

The Custom Gnotobiotic Isolator team's poster which they shared during their final presentation.

During the final Zoom class, seven teams of students gave presentations, explaining their projects in detail and showing slides of the various iterations of their design. Then, the following day, at an impromptu demonstration in one of Everitt’s student projects labs, several teams did live demos of their projects and how they work, giving Golecki one last chance to see and even try them out for herself before assigning that all-important final grade for the class.

The projects included a range of ideas: a Prosthetic Robotic Hand, a Custom Gnotobiotic Isolator, a 3D Bioprinter, a Surgical Trainer, Sensign Safety, the Pillsafe SmartCabinet, and an Ultrasonic Visual Aid. According to Golecki, the ideas for these senior projects came from many different sources. For instance, most projects had a sponsor—a faculty or community member or industry representative who had reached out directly to BIOE; other projects were proposed by students; some of this year’s projects were proposed by winners of the recent Carle Illinois College of Medicine’s Health Make-a-Thon competition. Still others came from some of BIOE’s existing relationships. Pprojects were funded by BIOE or the external/faculty sponsor.

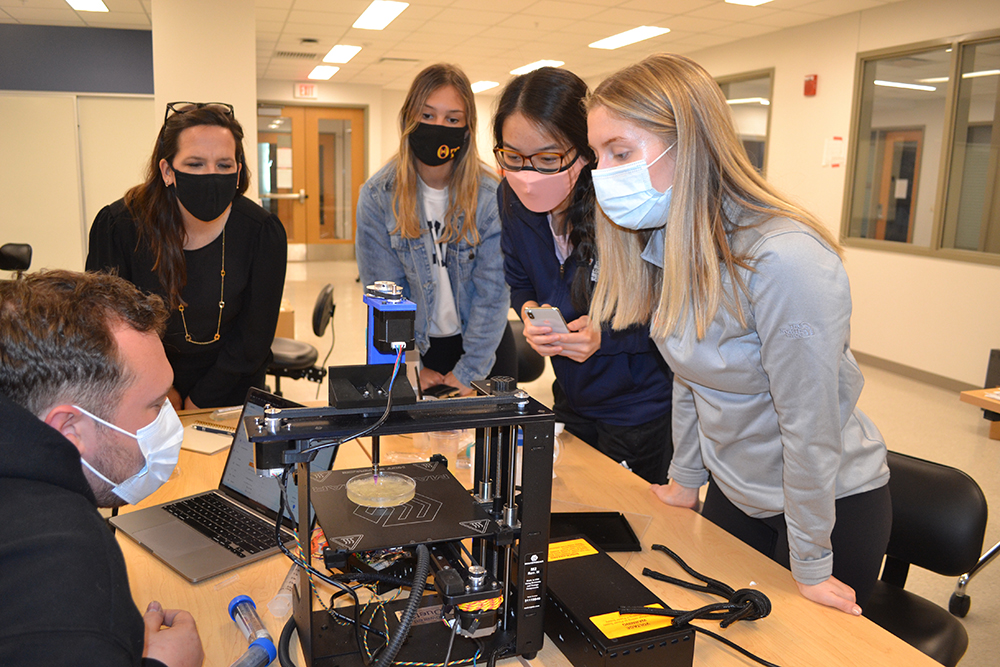

Elisandro Cabada and Holly Golecki chat with the 3D Bioprinter team during their demonstration.

One sponsor who requested help on a project, a 3D Bioprinter, was Assistant Professor Elisandro Cabada, a Medical and Bioengineering Assistant Professor in both the University Library and in the Carle Illinois College of Medicine. He reports that he and Golecki have been trying to expand 3D printing capacities for biomedical printing at Illinois, “because of how innovative it is, and because of the huge emphasis on biomedical bioengineering,” he reports, “not only in the Bioengineering Department, but also Carle Illinois College of Medicine research. We think the 3D models that we can get from this printer would be really useful for the areas of research and instruction for these two programs,” he explains.

He adds that sometimes, winners of the Health Maker Lab’s Make-a-Thon competition from the community who have dreamed up brilliant health-related ideas and gotten resources through the competition, don’t actually have a technical background. So, they then bring their projects to research groups or senior design courses like Golecki’s and have a group of students help create prototypes for them. This was the case for a couple of this semester’s projects.

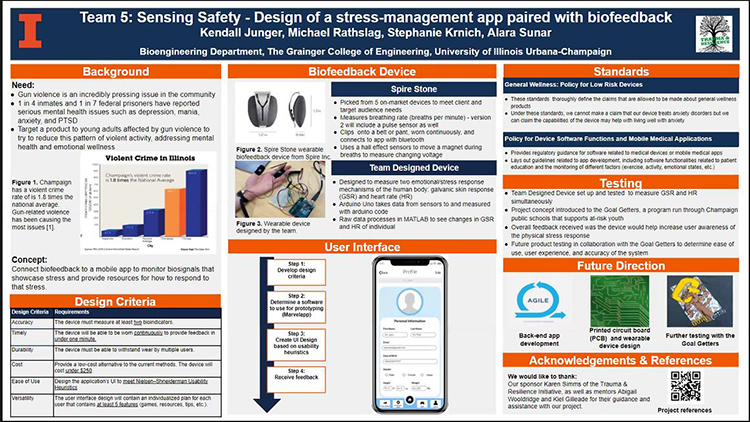

The Sensing Safety team's poster explaining their stress-management app, which they paired with biofeedback.

Cabada found being a sponsor of a BIOE435 project quite rewarding and had nothing but glowing praise for the students in his group. “Observing these students,” he claims. “It’s been pretty amazing considering how far they were able to get in such a very short time, under a lot of barriers such those created by the pandemic that the students have mentioned. So, I was very impressed. This type of accomplishment, even without the pandemic, would be remarkable, but seeing what they’re able to do and what they’re thinking of for the future of the printer itself, I think, speaks a lot to the students’ capabilities.”

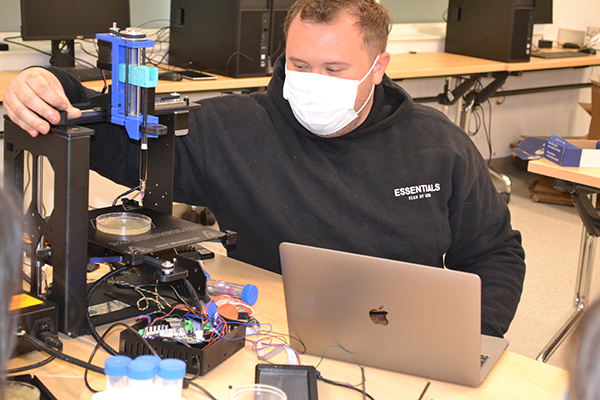

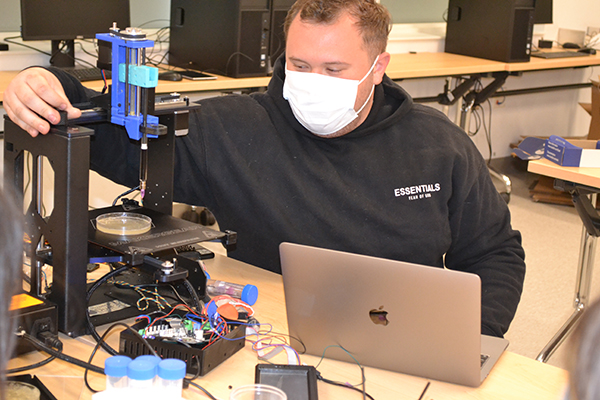

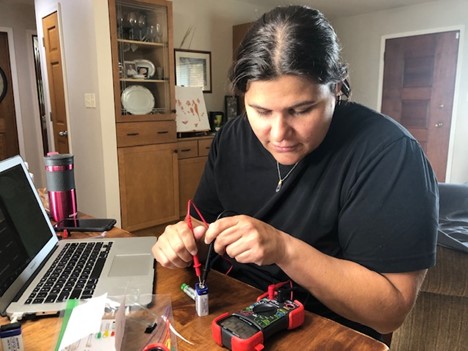

Joshua Whitely makes an adjustment to the 3D Bioprinter during the demo.

Sharing about his team’s experience was one member of the 3D Bioprinter team, Joshua Whitely, who eventually wants to do STEM cell research in an academic environment.

Regarding the challenges he and his team encountered in creating the 3D Bioprinter, he says, “I think that we had more issues with software and calibration than anything else. The physical construction was relatively easy, but the software issues were, I think, the more pressing issues, like just getting everything calibrated and configured properly. “

Did he learn anything through this project or through this class that he’s going to use down the road? “I’ve always been a pretty hands-on person,” Whitely claims, “so this just kind of reaffirmed it. But that’s kind of why I chose the project. I just liked doing hands-on projects.” Mentioning that he owns a car mechanic shop, he adds, “So, it’s just kind of in my nature to be hands-on with stuff.”

Whitely claims he and his teammates hadn’t had any issues collaborating with his teammates per se, but more so working in the current conditions due to the pandemic; for instance, he feels the inability to freely meet was the biggest challenge. He also mentioned various time constraints, such as shipping taking forever and the difficulty of setting up Zoom meetings, claiming it would have been a lot easier to “hop into a room and start working on something, saying, ‘Hey, we’ll be here from this time to this time; just come whenever and come help.”

For Whitely, the most rewarding thing about the project was “Seeing it work…I was only really happy whenever I saw it work,” he says.

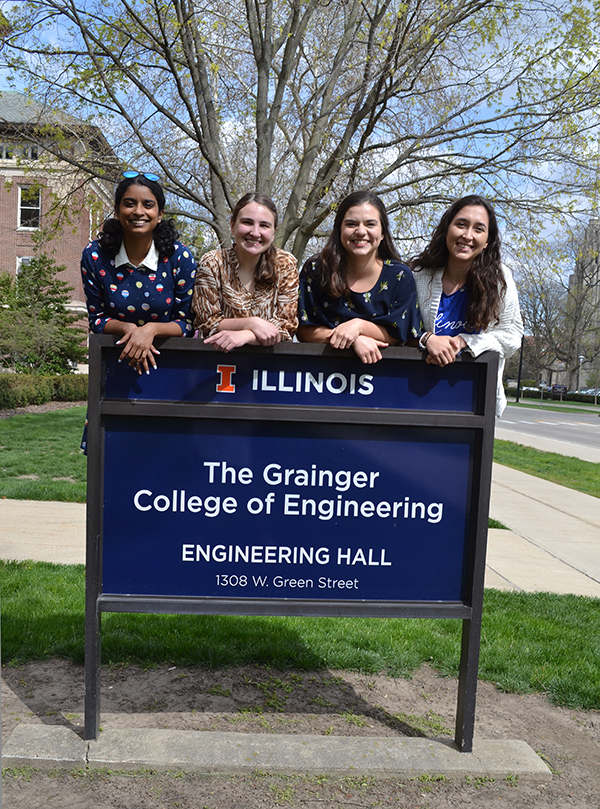

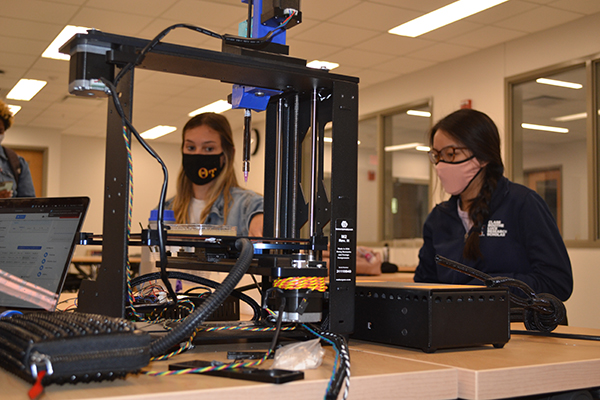

Lauren Ladehoff and Joy Chen, two members of the the 3D Bioprinter team.

BIOE senior Joy Chen was also involved with the 3D Bioprinter, which she says is able to print out 3D structures such as tissues and tissue scaffolding. According to Chen, 3D printers are generally very expensive—upwards of $10,000 for each printer, so, they’re not as accessible for everyone who might need to use them. “Our printer is transformed from a normal FDM printer,” she indicates. “So, it's a lot more inexpensive to build upon this printer and build the various parts that are needed to make it into the 3D printer. So, our goal with this is to allow students and teachers at the university to be able to print different tissues or 3D structures for classes.”

While they had done one test run before their presentation, during the demo session, they did another to print out alginate into a calcium chloride and gelatin bath where it would cross-link into the biomaterial.

Like Whitely, Chen agrees that the most challenging thing about BIOE435 was working during the pandemic. Plus, she personally worked virtually for the first half of the semester.

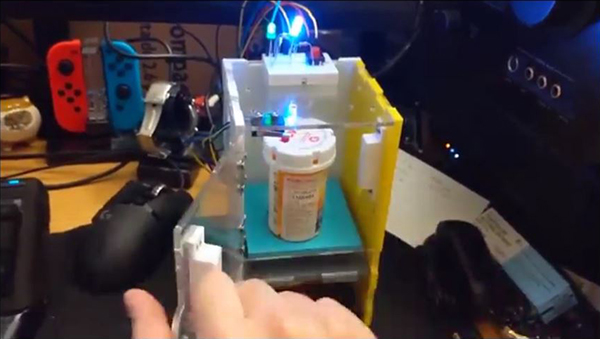

Image taken of the team's video showing the Pillsafe SmartCabinet in operation.

“So, it was just really important to keep communication going since different people were coming in at different times to work on different parts of the printer,” she acknowledges. Towards the end of the semester, she was able to come into the lab to work with the rest of her team, which she says was “Really cool to work on the final parts of the printer, get the materials and stuff ready to go.”

Chen shares a skill she gained from the class/project that she expects to put into practice down the road: “The whole process of starting by first identifying a problem, and then thinking of a solution, and then how that solution can be applied to different people is something that I picked up from this project, which I think will be important.” In fact, she intends to use it in grad school at Berkeley, UCLA in engineering. “So, I feel that part of the aspect is really important in engineering in general,” Chen adds, “just kind of understanding the problem and walking through the different pieces of how you could tackle that problem and put together a solution.”

Chen adds that she had a lot of fun working with her group in this class. “I feel I learned a lot. It was a great way to kind of finish off senior year with a design project.” Since the course had originally been two semesters, now combined into one, she calls it, “A bit challenging to kind of balance everything—doing the written assignments as well as coming in and building the actual project. But otherwise, I feel we worked well as a team, and I really enjoyed working with everyone on my team.”

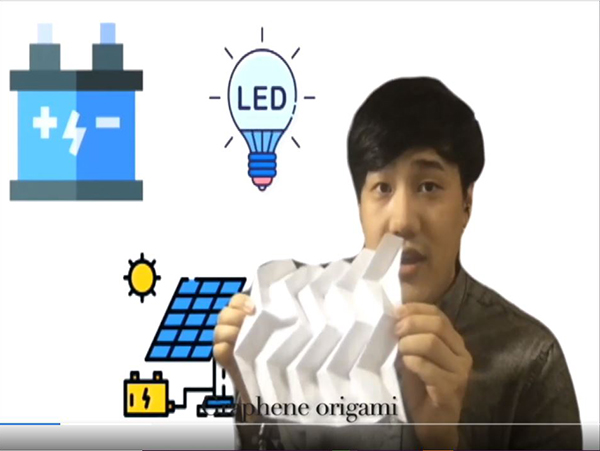

A video of BIOE senior Ben Salzberg testing his team's Ultrasonic Visual Aid shown during their final presentation.

BIOE senior Ben Salzberg was part of the Ultrasonic Visual Aid team; their device was intended to help people with moderate to severe visual impairments—an accessory that he claims might serve as a replacement for a white cane.

The silver objects (see image to the right) are ultrasonic sensors which send out high-frequency sound waves that bounce off an object and come back to the sensors. “These sensors are able to measure the time between when it sends the wave and when it receives it, Salzberg reports. “And with that, we’re able to calculate how far away an object is.”

The user gets feedback both through the handle’s vibrations as well as the sound it emits. For instance, the handle is equipped with multiple vibration motors with different patterns of vibrations that will notify the user, who will be able to feel it and also hear in order to discern which direction the object is—whether it’s to the left or the right or directly in front of them on the path, even above their head, telling them that they might walk into something.

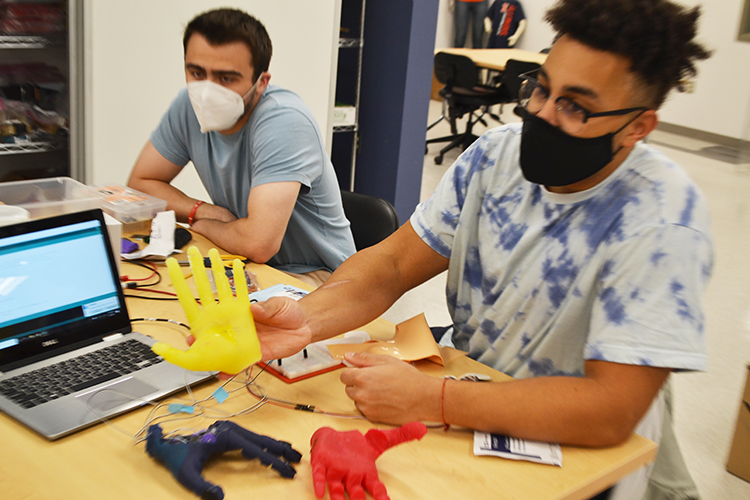

Riley Lehmann and Preston Njapa Njeuha demonstrate their Prosthetic Robotic Hand.

According to Salzberg, the most challenging thing about making their device was “just being able to get everything in a compact design,” he explains. “We also had some problems just getting the sensors to be accurate enough to be able to distinguish different objects. So really just combining everything together took a lot of work, but we are happy with the progress that we’ve made.

He indicates that the most rewarding thing about the project was being able to “Actually physically apply all the things that we’ve learned throughout our time at this school to make a stand-alone device over the course of this semester. That was really exciting to see!”

One skill Salzberg gained through the project that he knows he’s going to be using down the road was learning about how different sensors work, especially with microcontrollers, like the one they used that's similar to an Arduino. “It’s just how intricate they are and just the amount of different things that you can do with them. These are really interesting, and I think will be very helpful in the future.”

While he’s really happy with the way it turned out, Salzberg says one of their next steps is definitely minimizing the size of the device. “We want it to be super portable, handheld, and lightweight so that a person using it can use it all day without getting too tired.”

Holly Golecki interacts with her students during the Virtual Final Presentation.

Golecki acknowledges the main benefit of having seniors doing these seminal projects: “Senior capstone is a great opportunity for our students to apply the technical skills they’ve gained over their four years in the Bioengineering program to a completely new problem,” she explains.

Golecki says her favorite part of the capstone process is “watching the growth in the students’ thinking throughout the course. We encourage students to go out and talk to as many stakeholders as possible for the first month of the course, and it really opens their eyes to user needs and stretches them to think about their project in a new, human-centered way.”

Golecki really appreciates the breadth of projects that Bioengineering seniors work on. “In one course, we saw presentations from teams developing software for an anatomy lab VR simulator to teams building surgical isolators for gnotobiotic animal studies. It’s amazing to see the wide range of skills our students bring to these projects.”

Author: Betsy Innes, Communications Specialist, I-STEM Education Initiative. Photographer: Betsy Innes (unless otherwise noted).

For more I-STEM articles about Bioengineering projects courses, see:

- Bioengineering’s Golecki Uses Soft Robotics to Hook Students on Biomedical Engineering…STEM

- BioE Students Shine in Senior Design

- Bioengineering Undergrads Build Biobots in New BIOE 306 Course

Holly Golecki (second from the left) and the 3D Bioprinter team (left to right) Joshua Whitely, Lauren Ladehoff, Joy Chen, and Lauren Passwater, watch their printer during an imprompteau demo Golecki set up in one of BioE 435’s labs.

.jpg)