Liebenberg’s ME 270 End-of-Semester Main Project Presentations Showcase Students’ Manufacturability Redesigns

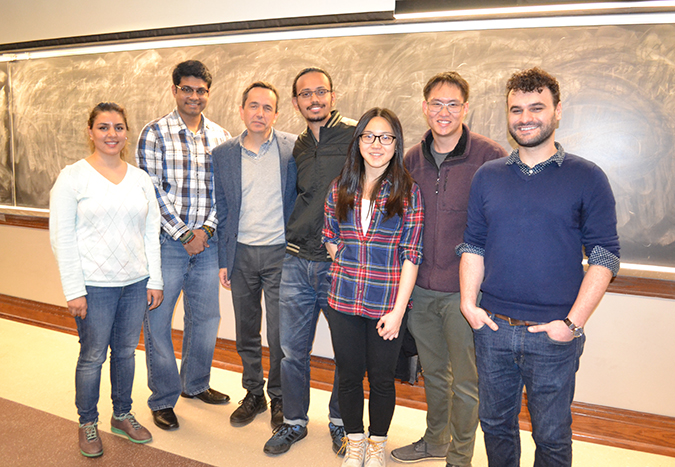

Professor Leon Liebenberg (second from the left) awards certificates to members of Team ABF-2 following their presentation of their redesigned Monkeypod.

December 18, 2018

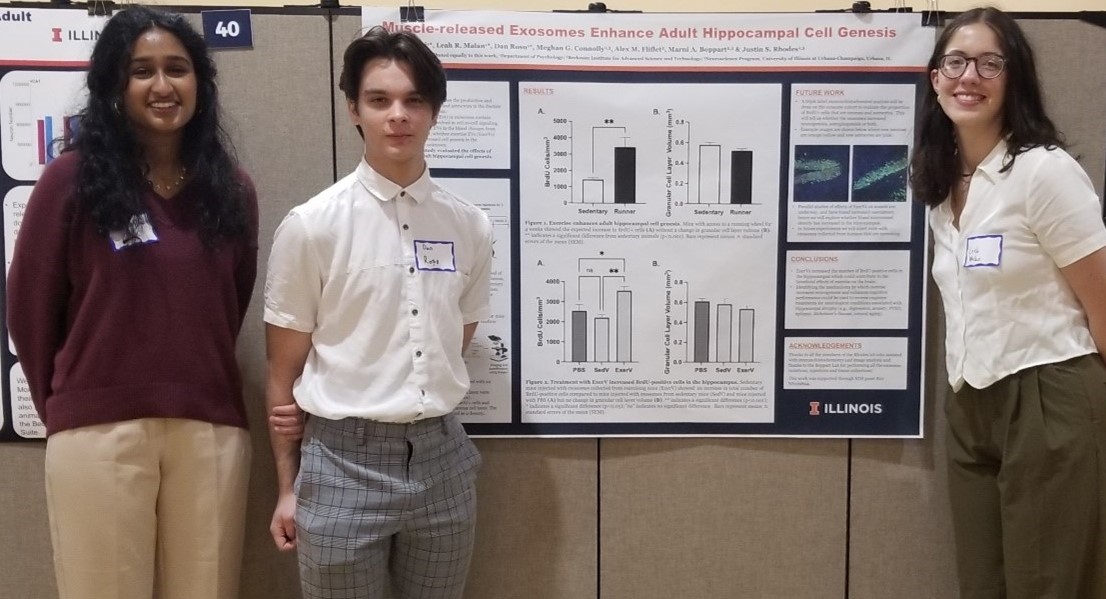

On Tuesday, December 11th, the top five teams in MechSE Professor Leon Liebenberg’s ME 270, Design for Manufacturability course presented their final projects before the entire class, as well as special guests, including both some current and emeritus professors and staff who contributed in some way to the students' projects. Attendees then voted on their favorite redesigned product.

The idea behind the course’s main project, Redesign for Manufacturability, was that teams of students were to purchase a product for less than $40 then redesign it so that it was simpler, used fewer parts, was easier to assemble or disassemble, could be made more inexpensively, and/or was easier to recycle. They were to test and evaluate their revised products and report their results in an e-portfolio. The top five teams were selected based on the following criteria: content and creativity, subject knowledge, composition, and contribution.

Photos of Team AB9-2's redesign of the Spieltek VR Headset. Above: the original two-piece face rest (with padding below). Below: The team's redesigned, single-piece face rest (with padding below). (Both photos courtesy of the team's main project e-portfolio).

All students pretty much followed the same procedures regarding their product redesign. First, they would reverse engineer the product—disassemble it to see how it works in order to improve or enhance specific aspects of the product. In addition, they would perform a QFD (Quality Function Deployment) analysis, which would include developing a list of customer requirements and narrowing those down to the most important design requirements, then improving one or more of those areas with their redesign.

To help teams decide which areas were the most important to address, some students completed a Pugh matrix, or decision-making model, useful for choosing between a list of alternatives. Another helpful tool some used was a DMFA (Design for Manufacturing and Assembly) analysis to assess whether, for instance, the redesign might increase the speed of assembly; a shorter assembly time would thus lower the cost. Other DFMA critera would be higher quality and sustainablility, increased reliability, or safety.

The next step was for students to create a CAD (computer-aided design) model of both the original product/component and for each redesign element. Using the 3D design, students then manufactured the part(s) via one of several manufacturing methods the course covered. Finally, to analyze whether the redesign would make sense financially, students used aPriori software to conduct a Product Cost Management analysis to determine whether the redesigned product could be manufactured more inexpensively than the original.

For instance, Team ABF-2, comprised of Kamil Nocon, Kevin Tuscher, Sitao Zhang, and Tim Culbertson, sought to improve the quality and function or to reduce the cost of the Monkeypod, a traveling mini tripod for cameras. After investigating online customer reviews, each of the four team members came up with three ideas, then narrowed the 12 ideas down to four: reducing the number of parts, a flashlight holder, redesigning the legs, and increasing the camera compatibility. So in response to a common consumer complaint about the numerous fasteners and parts necessary to attach/detach different cameras, they decided to reduce the total number of parts, which would most likely improve functionality while minimizing costs.

The next step involved creating a CAD model of the original product, then of the revised model, which had eight fewer parts than the original design, then 3D printing it. After analyzing their redesigned Monkeypod using aPriori, they determined that they had netted a 17% decrease in fully burdened costs and saved 32.5% in total capital investments.

Team AB7-1, Joey Bennett, Deandre Frisbie, Kevin Liu, and Joshua Wrobel, chose to redesign a crank-action, hand-crank drill. While they greatly improved the quality, the increased functionality was based on an increased number of parts, thus a greater fully burdened cost of $78.53, compared to the cost of the original hand-crank drill, $27.54. Thus, while their product would be of higher quality than the original product, it would be done with a much higher cost and longer manufacturing time due to the fact that their redesigned drill had significantly more parts. However, the original drill didn’t have as many advantages nor as much functionality as the redesigned drill.

Team AB9-2 discusses their redesign of the Spieltek Virtual Reality Headset during the final ME270 presentation.

Team AB9-2's redesigned VR (Virtual Reality) Headset (photo courtesy of the team's main project e-portfolio).

Team AB9-2's redesigned VR (Virtual Reality) Headset (photo courtesy of the team's main project e-portfolio).Regarding what the students learned through the class, in Deandre Frisbie's reflection on ME 270, he calls it "one of the most difficult classes that I have taken so far during my college career. However, it has also been one of the best learning experiences that I have ever had the pleasure to go through. The entirety of the class was filled with interesting and useful topics which I have no doubt will continue to be useful throughout the rest of my college and professional career."

Team AB9-2, Korkut Eken, Henry Feldhaus, Leah Groven, Karen Karapetyan, Jack O’Donnell, and Sathvik Rajgopal, redesigned a Spieltek VR Headset. After disassembling the original product, they decided to create a more cost-effective design by combining the two-part face rest sub-assembly into one piece, and producing the lens adjustment pieces from the same mold.

Another important change was to remove the mechanical fasteners in order to improve the assembly efficiency of the product. Thus, they decreased the number of parts by replacing the initial product’s 13 screws with snap fits. This greatly decreased assembly time and therefore assembly cost. It also reduced the number of standard parts that needed to be purchased. The total number of parts were reduced from 38 to 24 (around 37% decrease), and the Fully Burdened Cost decreased by $1.20 (around 22% decrease).

Regarding using what they learned in the class in the future, one team member, Henry Feldhaus, who is a member of the Illini Solar Car dynamic team, indicates that he intends to change the way he and his teammates design parts by making them more efficient both to use and manufacture. He reports, “It is quite obvious to me how useful this type of thinking can be applied in the industry, and I thoroughly enjoyed the hands-on learning style this course employed.”

Another team, comprised of Mary Ponicki, Theresa Ponicki, Frances Ponicki, and Isabel Rivera-Ruiz, redesigned the Tipeye 3D pen. First, they disassembled the pen and made a list, including the name, quantity, manufacturing process and material of each part. Then, based on their QFD analysis, they came up with twelve ideas for improving the pen, then narrowed them down to the following three:

Team AB9-2 discusses their redesign of the Spieltek Virtual Reality Headset during the final ME270 presentation.

The Ponicki tripletts exhibit their redesigned 3D pen.

- using snap fits for the outer shell pieces, instead of screws;

- using ceramic instead of ABS plastic for the heater nozzle, a safety issue which would help to reduce user injury via burns;

- add a laser beam drawing guide to make the product more user friendly. While this design would increase the total number of parts, it might also make the product more competitive. The team ended up implementing the snap fits.

While the aPriori analysis indicated that manufacturing the modified pieces would cost more than the original design, the assembly time would decrease because three screws were eliminated from the product. Plus, the snap fits would reduce the weight of the pen, making it lighter and easier to handle.

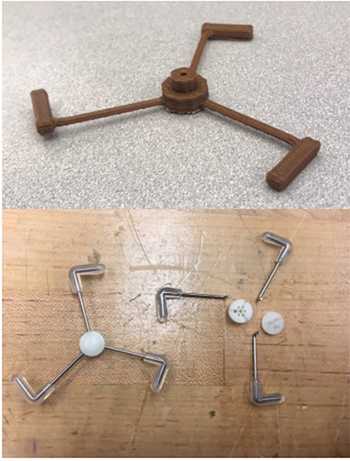

Team ABD-3, comprised of four MechSE (Mechanical Science and Engineering) students Rafael Cicogna Santos, Matthew Stoll, Isabel Ugedo Perez, and Maria Pilar Galainena Marin, redesigned a Kikkerland Wind-Up Toy. To determine how best to redesign the toy, they disassembled it, then analyzed every piece and material, conducting cost analyses, plus manufacturing quality tests. Based on a QFD matrix, they came up with the best ideas for an improved product.

First, they sought to improve the leg mechanism by creating one easy-to-manufacture piece to replace the current leg, comprised of seven different components, with the goal of improving assembly times. They also improved the main body, by creating a protective case which will increase the product life expectancy, and also improve its aesthetics. For example, the case would be see-through in certain areas, allowing customers to see the gears move (which the team members claim is “a really cool feature of our product"). Finally, they created a new prototype using CAD software then 3D printed the redesigned components.

According to Rafael Santos, in his reflections on ME 270, he reports learning the following about some manufacturing methods. Regarding additive manufacturing, he learned “about new methods of 3D printing which I did not know existed, as well as…better design practices when designing a product for 3D printing.” For metal casting, he learned about, “gates, pouring speed and pressure, cooling time, and many other concepts.” For injection molding: “I was able to physically understand how the entire process works and how each variable (such as gate diameter) plays a role in the quality of the final product.” For welding, machining, sheet metal work, and tolerance analysis, he was able to “review all of the concepts which I learned throughout my internship during the summer, as well as learn some new tricks.” Finally, he reports that for statistical design of the experiment, he learned “how to approach problems with an experimental methodology of testing and statistically drawing conclusions, mainly using the ‘2k Factorial Design’ method.”

Story by Elizabeth Innes, Communications Specialist, I-STEM Education Initiative. Photographs by Elizabeth Innes unless otherwise noted.

For more I-STEM articles about Leon Liebenberg's MechSE courses, see:

- MechSE’s Leon Liebenberg, SIIP Team Use Play-in-Learning Elements to Engage Students, Foster Active Learning

- ME370’s Final Competition—March of the Automata—Fosters MechSE Students’ Creativity, Perseverance, and Teamwork

Members of Team ABF-2 show off their redesigned Monkeypod mini tripod for cameras.

Below: Members of Team ABF-2 discuss their redesign process with members of the audience.

Team AB7-1, Deandre Frisbie, Joshua Wrobel, Joey Bennett, and Kevin Liu, discusse their redesigned hand crank drill with the audience.

Deandre Frisbie explains the processes his team went through when redesigning the hand-crank drill.

Professor Liebenberg (third from the left) with his team of ME 270 TAs.

Team ABD-3's redesigned Wind-Up Toy (photo courtesy of Team ABD-3's main project e-portfolio).

Top: The wind-up toy's redesigned legs. Bottom: Its original legs. (Photos courtesy of Team ABD-3's main project e-portfolio).

Top: The wind-up toy's redesigned legs. Bottom: Its original legs. (Photos courtesy of Team ABD-3's main project e-portfolio).

.jpg)