Two Illinois Students to Make Low-Cost Bionic Prosthetics More Accessible

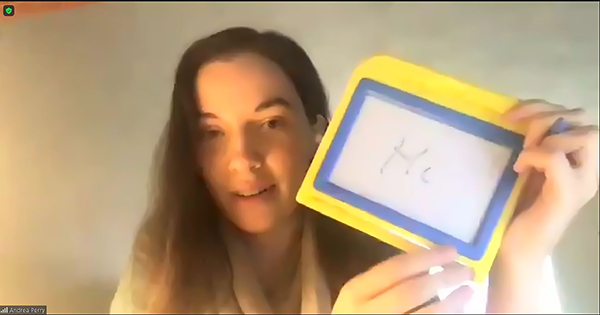

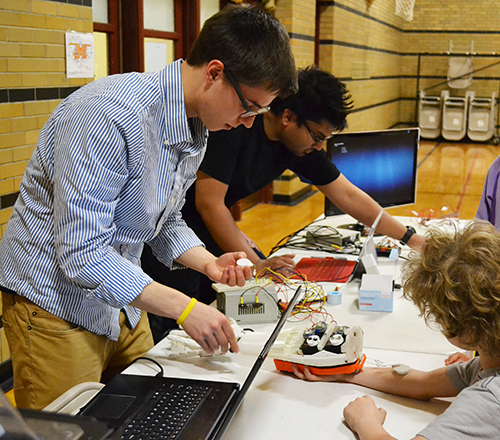

Illinois Neuroscience Ph.D. student Aadeel Akhtar (left) and MechSE junior Patrick Slade exhibit a 3-D printed bionic prosthesis like the kind they hope to manufacture in their new start-up company, PSYONIC.

April 30, 2015

Patrick Slade, a junior in MechSE, and Aadeel Akhtar, a Ph.D. student in Neuroscience, have the same tastes in a lot of things. For one, they both like to play guitar. They listen to the same kind of music. Members of the Bretl Robotics and Neuroscience Research Group, they both research bionic prostheses. And they both decided that someone should build more low-cost prostheses, so even people in third-world countries can have access to the technology. So in their spare time, they've started a company, PSYONIC. And they're on their way: Akhtar and Slade and their fledgling company recently won the Cozad New Venture Competition held on Friday, April 24 at the Illini Union; the prize: $25,000 to begin their company and start building prostheses like the ones they've been designing—only better, and at a lower cost!

Aadeel Akhtar interacts with a visitor at the Cozad New Venture Competition.)

They've both been preparing for this venture for a long time, but the two became interested in bionic prostheses via quite different routes.

Aadeel Akhtar has dreamed of doing this since he was seven. He describes meeting an amputee for the first time, in the summer of 1994: "She was a girl around my age, 7, growing up in poverty in Pakistan. As she hobbled towards me using a worn out tree branch as a crutch, begging for money, I became aware that there was a world of difference between us, even though we shared the same ethnic heritage. Unfortunately, I would meet many more like her through my experience in Pakistan that summer."

Akhtar goes on to describe how that experience was pivotal and set him on his current career trajectory:

"I still remember the girl to this day, and it makes me wonder how different her future would be if her crutch could be substituted with a working leg. That day was just one of the major stepping stones that led to my decision to pursue a career as a physician and an engineer, specializing in neuroprosthetics and physical medicine & rehabilitation."

Slade had no such epiphany, but he has enjoyed building things since he was a kid. One of his favorite toys? Legos. And his decision to become an engineer isn’t surprising; he’s just following in his parents' footsteps. Both are engineers: Mom’s a mechanical engineer; Dad’s in electrical.

Slade says that his folks didn’t push him into engineering. However, he does admit, “They encouraged me pretty strongly!” He says the minute he would express even the slightest interest in anything STEM-related, his parents, elated, would immediately encourage it. For instance, when he became interested in robotics, his folks ran out a bought a little robotics kit so Patrick could explore that interest.

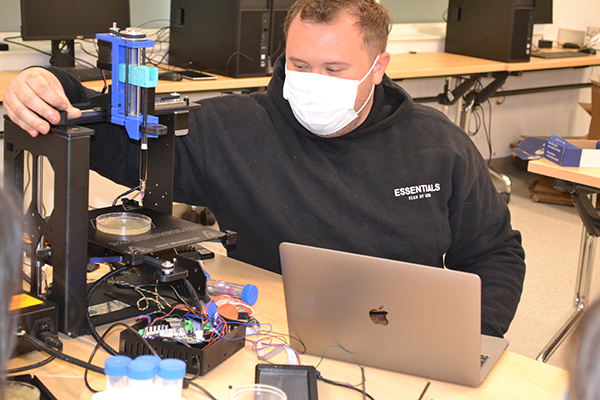

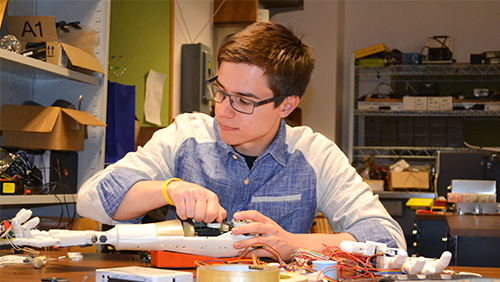

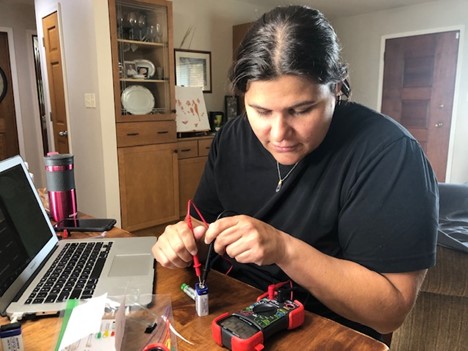

At work in the Bretl lab, Slade makes adjustments to a bionic prosthesis.

Not surprisingly, growing up in Libertyville (about a half hour north of Chicago), Slade was involved in a lot of robotics. In high school, he participated in a Science Olympiad robotics club, and was a member of the Robotics Club at school.

Slade ended up choosing Illinois because, “When I was applying to schools," he says, "I was actually looking for a really good engineering school.” He says Illinois was in a “great location, and a very reputable school, obviously.” He adds that Illinois “offered a lot of opportunities," and that because of the size, "basically there was any research group I could think of.”

Currently a contributing member of Bretl’s lab, did Slade specifically have his sights set on Bretl’s group when he first visited Illinois? He admits that he had checked out the different robotics groups on campus and what they do, and acknowledges, “I had looked at it, actually, before I came here.”

Slade holding a prosthetic hand, similar to the one he brought with him to his campus interview.

Slade had been interested in bionic prosthetics long before he came to Illinois and joined Bretl’s lab. He had already done some independent electronics projects in high school and had designed a prosthetic hand, which he brought with him to his campus visit, telling himself, “Oh, maybe this’ll help me get a gig!” Apparently it did.

Through some networking and a quirk of fate, Slade and Akhtar met. Akhtar, Slade's current graduate student mentor, was astounded at what his future labmate had been able to accomplish on his own, and quickly took him under his wing: "I was just floored to hear that he 3D-printed a prosthetic arm for fun during high school!" then shares an anecdote about how they met:

"It was serendipity," says Akhtar, then indicates that just a few weeks before Slade contacted him, he and a lab colleague had been discussing starting to 3D-print their own prostheses in the lab." Recalls Akhtar, "Patrick had no idea that we wanted to do that. So when he contacted us, I was absolutely excited, because here was someone who had done what we were about to set out to do, and not only that, he did it in his garage when he was in high school!"

Akhtar describes how Slade showed up, prosthetic in hand, and promptly began to contribute: "When he brought it in, we were immediately able to use it to test a method we developed for giving users joint location sensory feedback, resulting in a publication on which he was a co-author."

Akhtar enjoys working with Slade, partly because he's so innovative: "He's always thinking of new mechanical designs to improve the prostheses," explains Akhtar, then proudly boasts of his mentee's accomplishments: "In fact, he got a first-authored paper on one of his 3D-printed designs accepted at the 2015 International Conference on Robotics and Automation this May, which is one of the largest robotics conferences in the world."

Slade says he's learned a great deal from his mentor as well, who has taught him all he knows about research:

A Princeton student (right) visiting the Cozad Competition tries to control the prosthetic's movments via sensors attached to his arm, much as an amputee would do.

"Technically speaking I've learned a lot about how research works, from doing literature searches, to designing experiments, analyzing data, designing filters, machine learning algorithms, etc.

Slade says Akhtar has also fostered teamwork and leadership in him: "From a more personal perspective, I've learned a lot about leading a group and trusting others you work with. Coming in as a freshman," says Slade, "Aadeel was both welcoming and trusting by assigning me roles that older students and even other graduate students would typically do, and this really helped me feel as part of the team and led me to rise to occasion and do the best work I could."

Akhtar says the two will be working together down the road, too. Through their startup company, PSYONIC, they intend to revolutionize the market by providing low-cost prosthetic hands. According to Akhtar, "Our aim is to be the first commercially-available advanced prosthetic hand to have sensory feedback that can be developed at 10x lower cost than state-of-the-art hands on the market."

Slade shows off the prostheses he 3-D printed for @$100.

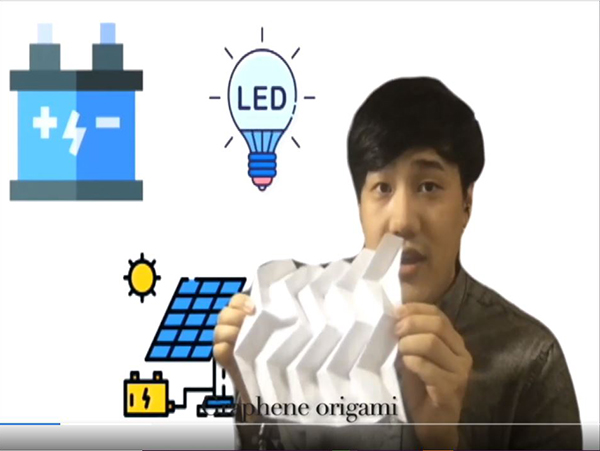

While Slade hopes to improve the functionality of prostheses, he’s also looking at making them low cost but with the same power and performance. While one emphasis of Bretl’s lab is neuroscience, Slade's emphasis is mechanical. In fact, he recently did a study with the goal of making the prosthetic more cheaply, which he did. He reports that the materials for the prototypes he built cost @ $100, vs. the $30,000–$40,000 most prosthetic hands cost.

“I think something that could really be improved is the functionality for the cost,” he explains. “So right now my electric hand is $30,000–$40,000, but I think you could make it for $1,000–$2,000 and have it be as good or better. The technology’s not that new and not that expensive.”

While Slade didn’t necessarily come to college intending to work in prosthetics, he admits that he had already had an interest in the field. (And after all, he did have the hand.) He likes the fact that, in addition to getting to address challenging engineering problems, he would be helping people. “I think it’s a really good application, because I know it has a positive impact.”

In fact, he’s already experienced how rewarding it is to make a difference in someone’s life through engineering.

He says that at the beginning of the summer last year, he and his labmates began a collaboration with a non-profit prosthetics group in Ecuador. Within two weeks, the group had gone to their embassy and gotten the money to bring his team down.

Amputee in Ecuador waits to try out the prosthesis. (Photo courtesy of the Bretl Research Group.)

Slade recalls his team’s reaction when they discovered they were heading down to Ecuador in four weeks: “So we were like, ‘Oh, God, we’ve got to get a hand together!’”

So they made a fully working prototype they could put on a patient, a man who had lost his hand 30 years earlier. Although such a long time had passed, the gentleman was still able to fully control the hand with the muscles in his arm. According to Slade, sensors put around the forearm read the muscle signals then send the data to a microcontroller (a processor like in a cell phone) in the hand, which analyzes the data then uses an algorithm to determine what the person is trying to do, such as a fine pinch vs. a power grip, and the hand does it.

Slade says the man thought their hand was pretty cool; his own hand, which was a more expensive version, could only open and close, but theirs could do a lot of different motions: a fine pinch, a power grip, a three finger grasp, and so on. “So he thought that was really amazing that he could do so many more things with it,” Slade recalls.

Unfortunately, Slade didn’t get to go to Ecuador; his passport hadn’t come in time (this has since been remedied). But he was still heavily involved, helping to “figure out different things that were going wrong with the hand,” from Illinois.

Also very rewarding was the Goldwater Scholarship Slade recently received, most likely based on his cutting-edge research in bionic prosthetics. One of around 300 students across the nation to be so honored, Slade describes the scholarship as primarily research-based and for undergrads who are interested in continuing their education and seeking a Ph.D. in the future.

“They’re basically trying to find the kids who they think will make the research impact,” he continues, “and who are interested in research.” Like Slade.

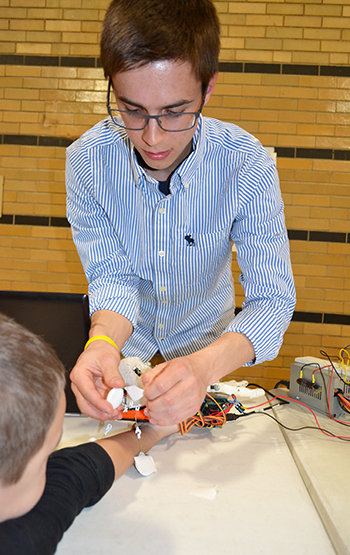

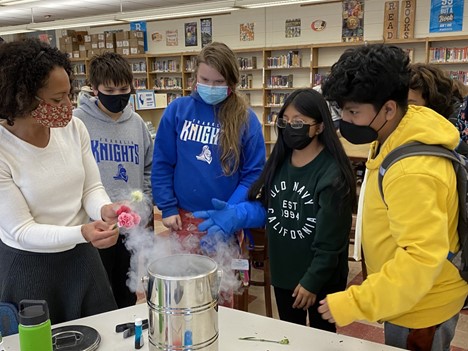

During Leal Science Night, Slade places sensors on a young visitor so he can operate the bionic hand himself.

But research isn’t the only thing Slade likes to do. He says that when shopping for a university, he was also looking for extracurricular activities—“A big variety of things that I could do,” he explains—including hockey and Ultimate Frisby. (Unbeknownst to this writer, frisby has evidently evolved past leisurely tossing said object back and forth in an idyllic setting). Ultimate Frisby appears to be more competitive, with teams of 7 on 7 which try to score touchdowns.

In addition to hocky and Ultimate Frisby, Slade likes sports, rock climbing, and hanging out with his friends. “Sometimes we go to trivia night at bars,” he confesses.

What’s Slade’s dream job down the road? He says it will definitely incorporate research, either in industry or academia. He also likes teaching.

In fact, Slade and Akhtar have tried their hand at it on several occasions during some STEM education outreach events they've been involved in. They recently participated in the Leal Science Night, where they demonstrated bionic prostheses to local youngsters.

Slade, who had also participated in Engineering Open House 2015, says the outreach was similar to EOH, but with a little younger audience, “which I think is even better,” he claims. “Because I think by middle school, high school, kids already know what they’re interested in, so to show them stuff like this at an even earlier age is great. Get them thinking about it. I know if I had seen stuff like this, I would have been like, ‘Wow! I’m gonna’ go build that out of Legos.’ I would have been really interested.”

During Leal Science Night, Patrick Slade (left) and his graduate student mentor, Aadeel Akhtar, demonstrate to a young participant how the bionic prosthesis works. The youngster was able to successfuly operate the prosthetic via the senors attached to his forearem.

Akhtar believes outreach is important in order to make the public aware of their work: "As a future physician and an engineer, I believe it is incredibly important to be able to disseminate publicly the importance of the work that I do. We don't just do theoretical work in our lab—we apply our neuroprosthetics research clinically in order to benefit those who need it."

Akhtar also hopes to "inspire a new generation of students to look at the intersection of STEM fields like neuroscience and engineering to solve problems that we can't even conceive of being possible today."

And while packing up all of the equipment and the prostheses to head to an outreach like the one at Leal Science Night is a lot of work, Akhtar believes it's worth it if some awestruck, starry-eyed youngster ends up choosing his field.

"During my undergraduate career, I was inspired by the incredible advances in bionic limbs made by the Center for Bionic Medicine at the Rehabilitation Institute of Chicago," admits Akhtar. "I hope I can inspire people to explore this field the same way the Rehabilitation Institute of Chicago inspired me."

Story and photographs by Elizabeth Innes, Communications Specialist, I-STEM Education Initiative.

More: MechSE, Student Spotlight, 2015

For an aditional article about the Bretl Group's recent work in Ecuador, see:

Leal Science Night organizer and Illinois Physics professor Brian DeMarco (left) looks on as Patrick Slade (right) explains to him and other visitors how the prosthetic haad is fabricated via 3-D printing.

.jpg)