Gulyash, MechSE Machine Shop Solve Problems, Save Money…and Recruit

January 20, 2015

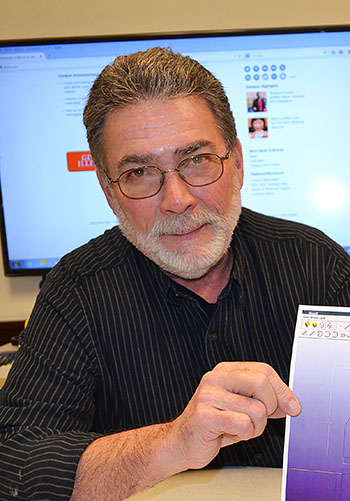

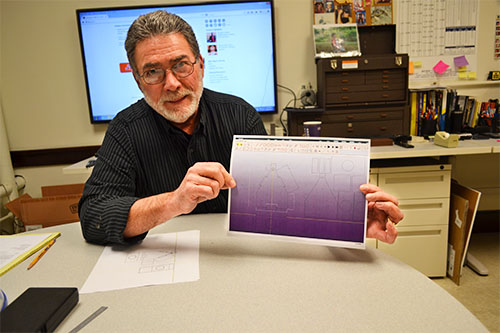

Clifford Gulyash, MechSE Machine Shop Supervisor

“What I have is a lifetime of solving problems by building anything and everything that’s been given to me.” – Clifford Gulyash

Clifford Gulyash, who heads up MechSE’s Machine Shop, doesn’t have an engineering degree. “What I do have is a basic understanding of how to make things,” he modestly explains. And he’s been making things since he was a six-year-old.

He shares an anecdote about his early proclivity for making things: “I started building as soon as I could pick up a hammer, and when I was five or six, I built my first go-cart, put a sail on it, and ended up getting into trouble going down the street. That’s a true story.”

His love of problem solving led to his going into the machinists’ trade, where he worked in custom shops, doing mostly prototype work. Then 22 years ago, he got his dream job: working with like-minded folk to solve problems at a world-class university.

“Working here in the department as a machinist, it doesn’t get any better than that, because this is where all the fun stuff is, right here in engineering. Because these people, on a daily basis, they sit up at night and they dream about solving problems.”

Cliff Gulyash and his Machine Shop cohorts mostly work with graduate students, research scientists, and some engineers. And their work often involves thinking outside the box. For instance, one neuroscientist came into the shop recently complaining that his sensor cap was having issues with outside interference. Gulyash told him, 'You need a Faraday Cage," (an enclosure formed by conductive material to block interference from external electric fields). So he consulted an expert—Granny—who informed them that a sewing pattern for a cap could be purchased online, which they did. They used it to cut pieces from the researcher's metal screen material, used a hot glue gun to "sew" the seams, and constructed a Faraday Cage cap.

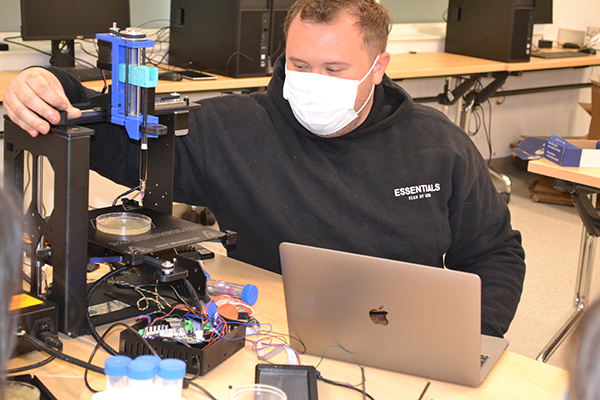

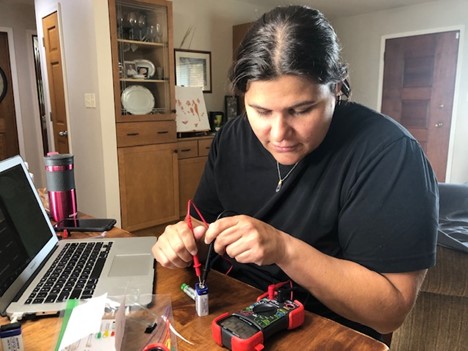

Above: IT specialist Stuart Turner (left) and Cliff Gulyash look on as one member of the team tries out a new toy, a microscope that allows them to view what they're doing while working with very small tools on their high-speed milling machine. For example, the magnified tool on the laptop screen is about the size of a human hair. Below: Machinist Kyle Cheek plays with the new gizmo.

Another creative solution they came up with involved very small tools that can't really be seen with the human eye. "And now I'm 62 years old," Cliff complains. "My eyesight's even worse. So as my eyesight has gotten worse, needing bifocals and such, I'm constantly thinking, 'There has to be a way to improve this!'" So their tech guy, Stuart Turner, found a microscopic camera for $30 which can be connected to a laptop to allow them to view really small objects up close.

Another group of clients the machine shop also works with is undergrads; in fact many of their regulars are undergrad students from ME470 Senior Design class. “That’s a lot of fun!” he admits.

“But they come in with ideas about how to do things, and then we make it possible to actually fabricate the stuff and do it as cheaply as possible,” Gulyash continues.

Does he ever tell them, “No, this idea isn’t going to work? “Ummm…No, I try not to do that,” he hedges. He indicates that he tactfully suggests, “‘Maybe you could go back and rethink this.’”

Does he ever tell them, “This is a bad idea!”? He says no. “These are senior engineering students who are a heartbeat away from having a degree. I don’t have any right to tell them, ‘No, you can’t do this!’ But he has no qualms about speaking up in order to help save them money: “What I do is try to encourage to get them to thinking on how to build items they can put together as cheaply as possible. Because they’re on a really strict budget. They only give them so much money to get things done.”

Joe Muskin shows off the control box the shop built and explains how it works.

While he loves to design and build things, he admits that he has an ally when it comes to building things as cheaply as possible: Google. “Just to give you an idea; today a gentleman came in, and wanted to know if we could bend this angle out of aluminum. I said, ‘Well, come here…Look, you could buy this for $6.67!’ Most of it is just doing some research. Regardless of what you want to fabricate, you can do yourself a big favor by just going to the internet!”

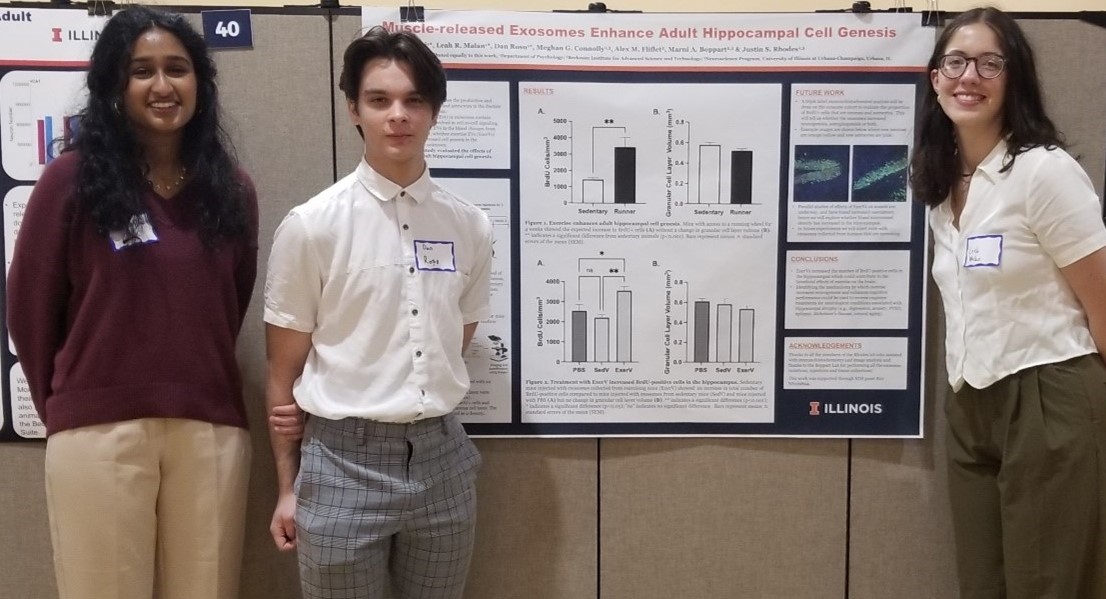

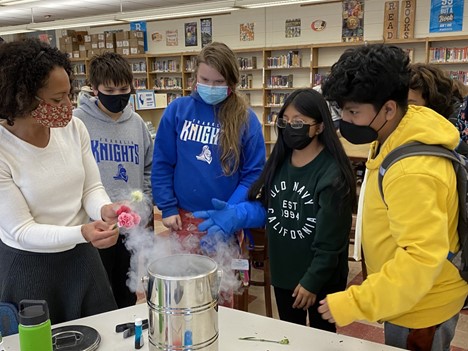

The folks in the Machine Shop also do the occasional outreach project, such as one they did this fall helping Sharlene Denos’ senior Engineering Class at University Laboratory High School (Uni), who recently designed and built a Wind Maze for Champaign’s Orpheum Children’s Science Museum. Gulyash and his cohorts constructed a couple of the key components for the project based on the students' designs: a control box and an input box.

Ironically, Gulyash knows how powerful of a learning tool a wind maze can be. Not too many months before, he had taken his grandson Grady to a children’s museum that happened to have an air maze. “He got on that thing, and we had a hard time getting him off of it, because he just loved it so much!” Gulyash reminisces.

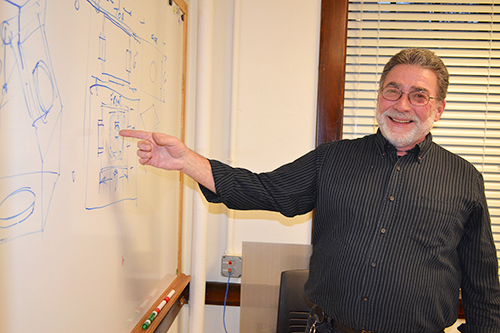

Cliff Gulyash explaining his design for the wind maze components..

When describing his part in the project, he hopped up to his white board and explained the design, the mechanics, and how it was supposed to work, displaying the drawing he’d made of the design for the proposed air maze, which he’d nicknamed “Joe’s Bird House.” But even though he’d just seen another wind maze and no doubt had known exactly how to design it, he’d let the students do it.

“What I did with the students was enjoyable, because I let them tell me what they wanted to do. They designed this. I just asked them the appropriate questions…They set all the rules.”

Of course, one important consideration was safety: “These are items that are going to be used by children, so they had to be safe, smooth, no sharp edges.”

He says the students met with him, they designed the two boxes, ordered the materials, then he and the other guys in the shop built the two boxes. He says they even assembled it, bolted it together, and tested it to make sure it would work. But lest they deprive the students of even the smallest learning experience, they then took it all apart again and told the kids, “Here you go.”

Says Gulyash: “I let these high school students tell me what they wanted to do, and we went ahead and did it, and tried to do it in a way they would actually be involved in the assembly of it.”

Uni student prepares to install the blower motor in the wooden box they constructed to house it.

Gulyash said the blower motor was key to the operation of the wind maze: “It requires a large volume of air into a 4-inch tube to propel these objects.” Of course, once a powerful enough motor was purchased, it provided another obstacle; it needed an adapter that would go from a square shape to a round shape over a short distance.

So Gulyash contacted Brian Dunkman, owner of Allied Mechanical Services, who has done a lot of work for MechSE, and asked him for a favor. “He came in; he looked at it, and said, ‘I’ll just make one,” Gulyash reports. “When do you need it?’ Dunkman got it made and delivered it two days later.

In his office in MechSE's Machine Shop, Cliff Gulyash exhibits the designs for the wind maze components.

How difficult was the project? Citing an old design expression, “Form follows function,” Gulyash claims “This bird house, it designed itself, just the way the input box designed itself.” Of course, the students learned another important lesson once the maze was done: sometimes a project needs tweaking. “It didn’t act like I thought it would,” Gulyash admits. So the students had to bring it back so they could make some changes—which he had already predicted:

Machinist Kyle Cheek shows a part he made for an automated wheelchair.

“I knew that this was gonna’ be one of those things that we put together, and then we’d have to fine tune it, and that was the case.” But glitches don’t phase Gulyash, who is an old hand at it: “What I have is a lifetime of solving problems by building anything and everything that’s been given to me.”

When Joe Muskin approached him about helping the Uni students, Gulyash indicated that MechSE has always encouraged outreach: “As far back as I can remember, in this department, they’ve always really been giddy about outreach programs, no matter what it was, from Placid Ferrierra, the department head, on down to all of the guys in the shop.”

For one, Gulyash sees outreach as a great recruiting tool. “I told him I’d love to. It’s great…Anything that this department can do to encourage any student out there to get into engineering, it would be just wonderful. I told Joe, ‘It’s not going to be that long. To see these high school students come down here working on this project, it is instantly clear that these people are going to be walking the halls here in no time at all’…So why not help them? It’s just a no-brainer.”

Several members of the Machine Shop crew: Gary Sedberry, supervisor Cliff Gulyash, and Jeff Smith.

But even though the department encourages outreach, Gulyash knows that someone has to foot the bill to pay for Machine Shop services. So he solved that dilemma by volunteering his time for the project. “I personally will do all I can to put this project on me and my time, so that it doesn’t reflect on time on the shop. Drawing before work or during lunch.”

Why donate his free time for the project? He’d like to see the students attend Illinois. “I want ‘em to come back next year.” And he sees his machine shop as one component of the recruiting process:

“I’d really hope that this is an opportunity for this school to utilize the machine shop and the basic groundwork of engineering that we do here.”

For additional I-STEM articles about the wind maze, see:

For additional I-STEM articles about MechSE, see:

- MechSE's Gaurav Bahl Promotes Outreach and Undergrad Research

- SungWoo Nam Creates Virtual Lab, Promotes Undergraduate Research

- Open House Showcases MechSE for Prospective and Current Students

Story and photographs by Elizabeth Innes, Communications Specialist, I-STEM Education Initiative.

More: Faculty Feature, MechSE, 2015

Left to right: MechSE's Machine Shop staff by their new toy, a Water Jet. The only one of its kind at Illinois, it has many fans across campus because of its capabilities: it forces a highly-pressurized (50,000 psi) stream of water, combined with a very fine abrasive (which Gulyash says is finer than sand and almost feels like baby powder) through a tiny jet the size of the end of a pen, to cut metal very quickly.

.jpg)