C-U Fab Lab Fosters Creativity in Local Youth

Student and C-U Lab worker communicating with other Fab Lab users around the world via the Fab Lab network.

August 30, 2010

A local young Tom-Edison-in-the-making with an inclination toward invention needs to look no further than the Champaign-Urbana Community Fab Lab. Located on the University of Illinois campus, this fabrication laboratory contains state-of-the-art, computer-controlled manufacturing tools designed to foster creativity and innovation in local inventors, both young and old. The Lab, like its sister Fab Labs around the world, is equipped with commercially available rapid prototyping manufacturing equipment, such as a laser cutter for carving out 2D and 3D structures; a precision milling machine for 3D molds or circuit boards and a larger one for making furniture or larger parts; rapid prototyping equipment for 3D printing with plastic; a sign cutter for creating graphics or plotting flexible electronic circuits; and electronic assembly tools. Would-be inventors can dream up a design, create it on a computer via easy-to-use design software, then use lab tools to create it. Another key feature is the Fab Lab network, an online community which allows local Lab users to present their problems and get advice from Fab Lab users around the world.

Volunteer worker assisting youth in Lab.

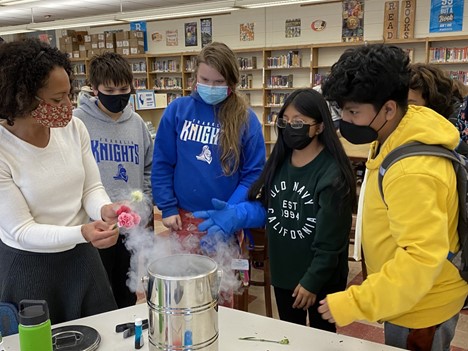

While not yet open to the public, the recently established Lab conducted a pilot program this summer with youngsters from Don Moyers’ Boys and Girls Club. Focusing on junior high and high school students, the Lab is also partnering with Champaign and Urbana school districts. Impressed by the lab’s capabilities, one elementary school principal begged, “Will you take my third graders?” Other partners include Parkland College and University of Illinois units, such as Engineering; Fine and Applied Arts; Education; Labor and Employment Relations; CITES; I-STEM; and ICHASS (the Institute for Computing in Humanities, Arts, & Social Sciences).

Heavily involved during the C-U Lab’s start-up phase, Betty Jo Barrett, who teaches sociotechnical systems at Illinois, describes the lab as “just a wonderful opportunity for people to learn about technology, something entrepreneurial.” She succinctly identifies the lab’s major benefit— “You can build almost anything!”—and goes on to elaborate: “Users can take an idea, crystallize it in a lab, and make a working prototype.”

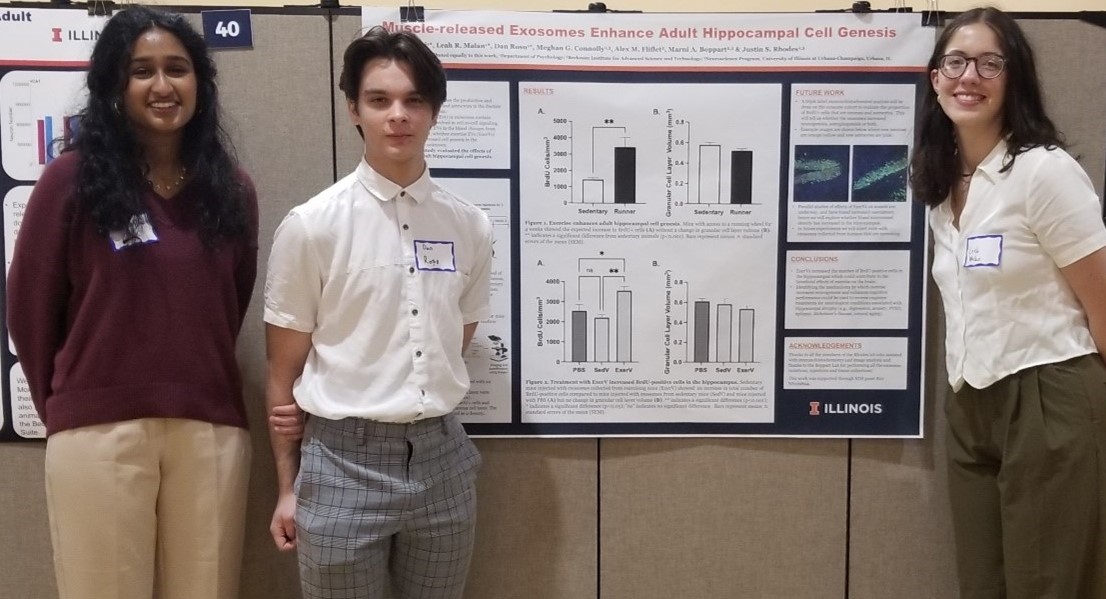

Youngster individualizing her "tin can robot."

Barrett has seen the “light bulb” turn on when a youngster takes ownership of the Lab. Local youth in the pilot project used a computer to create a design, transferred it, and then actually operated the laser cutter. Youngsters made small tin-can robots from kits using the laser cutter to cut wooden lids for the cans and the vinyl cutter to make the outside skins. While Lab staff worked hard to keep it fun, they also taught; youth came away from the experience understanding a dizzying array of fabrication jargon, such as scope, proportion, rastering, and vector and—another plus—they had to use lots of math—in the summer, no less.

One of the driving forces behind the C-U Fab Lab, Illinois’ Dean Joel Cutcher-Gershenfeld discovered the value of these labs while volunteering at the first Fab Lab, which his brother Neil Gershenfeld founded in Boston several years ago as the education component of an NSF grant to MIT’s Center for Bits and Atoms. The original Lab spawned a concept which has taken off; more than 45 labs are now located in 16 countries; each lab’s unique, distinctive characteristics enable local communities to create solutions to solve problems, and thus improve the quality of their lives. The labs can serve an important function in the community, as the residents get into the mindset that they can create what they need, whether it be education, an invention, or a new way to use a traditional tool. For instance, the Lab in South Africa created cell phone antennas; sheep herders in Norway made tracking devices for their sheep; in a Ghana village, children used the Lab to make circuit boards, which were in short supply; the one in Costa Rica made tools for use with computers. And now, there’s one in Champaign-Urbana. In fact, more new labs will likely be springing up in the US soon, since the House of Representatives has just passed HR 6003, which indicates US government support for design and fabrication as essential literacy in the 21st century and calls for a national network of Fab Labs.

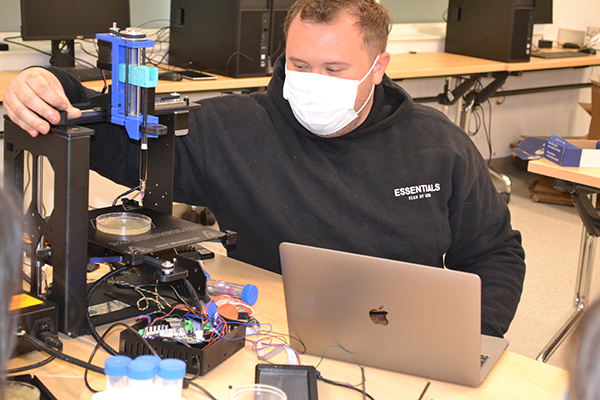

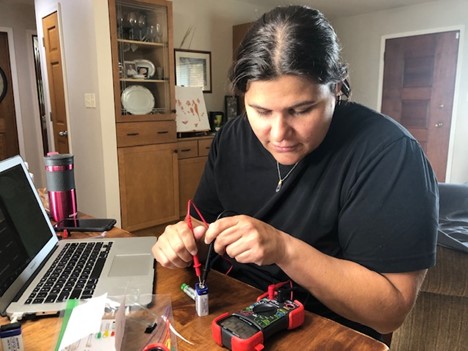

Student using computer to create a design at the C-U Fab Lab.

While it does not yet have a “signature fabrication,” thanks to start-up funds from the Office of the Provost and to the many people who donated both equipment and time, Illinois’ Fab Lab is now officially up and running, with the grand opening slated for November 11, 2010. However, since the Lab will be open to the public only if it has sufficient staff who are certified on using the equipment, staff are seeking more volunteers—people with expertise: students, professors, engineers, computer scientists, and retirees, such as retired engineer Gary Watson, whose help has been invaluable in setting up the lab. One potential project those heavily involved in the Lab are considering is writing a “how-to manual.” The subject matter: how to set up a Fab Lab.

More: K-12 STEM Outreach, Champaign-Urbana Community, Fab Lab, 2010

.jpg)