Amos's Atomic Microscope Gives Students Close-Up Look at Cells

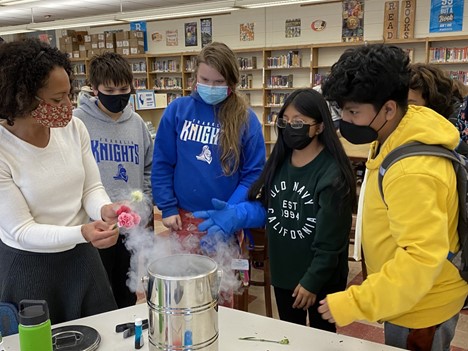

Dr. Jennifer Amos demonstrates Atomic Force Microscope's imaging capabilities during IGERT session.

August 26, 2011

A few adventurous young bioengineers are taking cell research to a whole new level—the atomic level. University of Illinois bioengineering students now have access to a new tool for looking at cells called an Atomic Force Microscope (AFM). In March, the Roy J. Carver Charitable Trust provided the $290,000 machine, in the form of a grant, to the university and to bioengineering lecturer Jennifer Amos. Amos will lead a new class this fall called “The Bioreactor Lab” that will focus on teaching students about the use Atomic Force Microscopy in bioengineering.

AFM is a tool that has been in use for decades, but has only begun being used for biological data fairly recently. As technology has improved, an optical element has been added that allows bioengineers to look at cells in ways that weren’t possible until just a few years ago. When used in conjunction with microscopes, AFM can create images that combine mechanical and optical data, and allows for close-up viewing of individual cells.

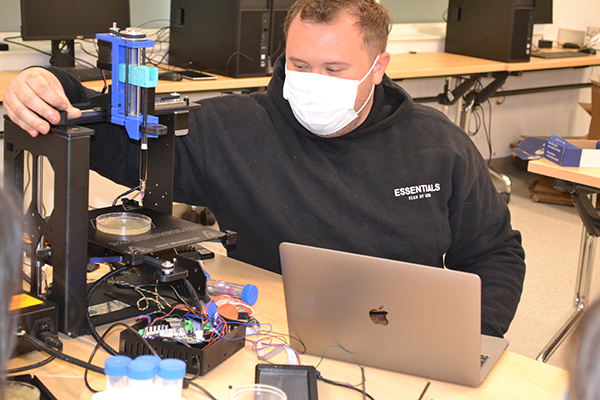

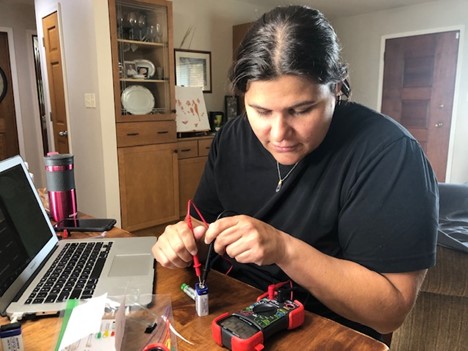

IGERT students and Atomic Force Microscope.

Amos led an AFM-focused module at the Integrative Graduate Education and Research Traineeship (IGERT) mechanobiology workshop this summer that gave some students an introduction to atomic force microscopy. She discussed with the workshop participants specific ways that they could each integrate AFM into their own research activities. Amos believes that the IGERT workshop was incredibly successful. “I was able to get seven people excited and immediately working on experiments using AFM, just through the three hours I spent with them,” she said.

Students in the new “Bioreactor Lab” class will get to spend the fall semester using the new microscope to study tissue cells and will conduct a series of tissue-engineering experiments. Amos will lead the class of undergraduates through the processes of assessing biocompatibility, testing for biofunctionality, and finally creating heart, tendon, and ligament tissues. In addition to AFM, students will be trained in things like cell staining, fluorescent imaging, and even building bioreactors in the machine shop. Many of the students taking the new class are on a track to study cell and tissue engineering throughout the course of their studies at the university. However, because of the overwhelming interest in the class, other bioengineering students are participating as well.

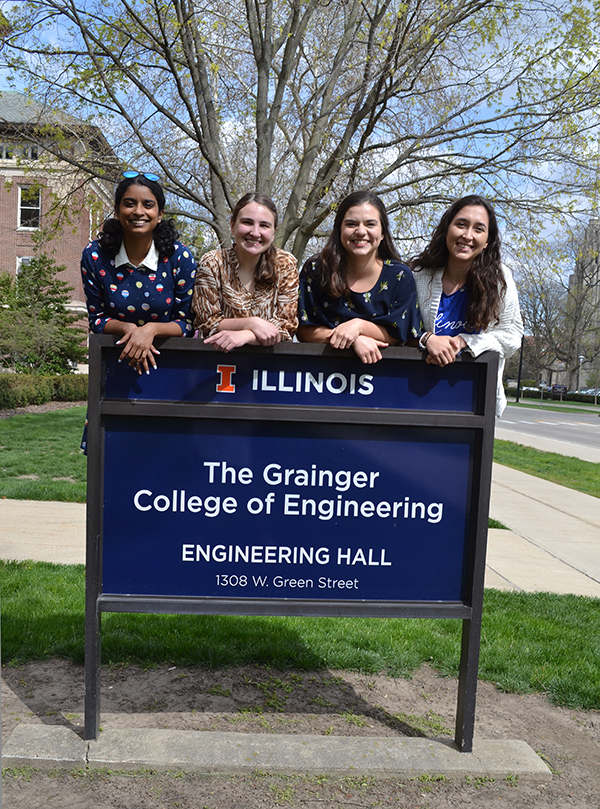

IGERT students enjoying the AFM's 3D capabilities.

According to Amos, this class is unique because it will teach senior undergraduates the graduate-level skills that will prepare them for lab work and for work in the bioengineering industry. “We feel like it makes them more competitive. Those skills translate to industry and it just helps them really learn how to design experiments,” she said.

The course will require a high degree of dedication from students, who will spend a lot of time working independently. “They’re expected to basically function as a grad student or as a working individual, so it’s a heavy responsibility, but they’re really excited to do it, and I think for them it’ll be almost like doing their own independent research,” she said.

The class will end with students actually designing experiments based on their own interests, and using the AFM and optical imaging techniques that they will learn. “I think it will be a really unique opportunity for them,” said Amos.

More: Faculty Feature, Funded, IGERT, Undergrad Education Reform, 2011

.jpg)