Local Teacher Uses Project Lead the Way to Prepare Next Generation of Engineers

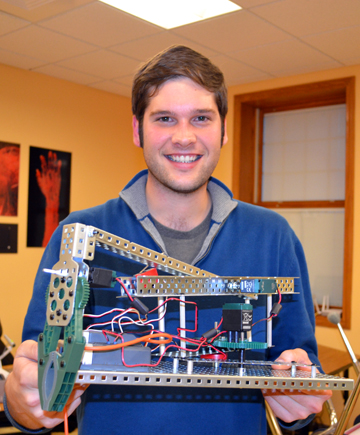

Next Generation School Science Teacher Bryant Fritz displays the Pick and Place robot a team of his eighth grade students designed as part of their Project Lead the Way robotics unit.

February 20, 2013

"Mr. Fritz, I'm going to be an engineer!"

This is what science teacher Bryant Fritz's middle school students are telling him when they greet him in the hallway these days. For a couple of years now, Next Generation School in Champaign has been incorporating Project Lead the Way STEM curriculum as part of its science curriculum for the 6th–8th grades, and it seems to be leaving an impression.

For the last twelve weeks, Fritz's 6th graders have been learning about renewable energy in a unit called "Energy and the Environment." The 7th graders, in the "Design and Modeling" unit, have been designing for production, while the 8th graders have studied "Automation and Robotics."

Just in time to serve as students' exhibits for the school's Science and Engineering Fair in February, the pièce de résistance of each unit was a final hands-on project. Because Fritz considers learning to communicate and collaborate to be important, for the first time in the history of the school's science fair, he purposely assigned students to work in groups of two or three. "That is a big communication deal, learning that engineers have to be able to communicate, and work with each other, and document those things in their notebooks."

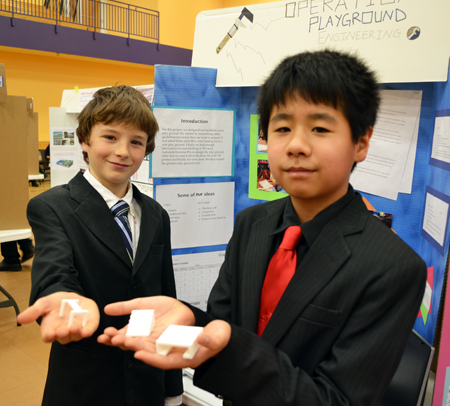

During during Next Generation's Science and Engineering Fair, seventh grade students from the Operation Playground team display models of playground equipment they designed.

The final projects built on all that students had learned during the unit. For example, the seventh graders were to design a playground. However, before they could begin their designs, Fritz had them interview primary students, asking, "What kinds of things do you like on a playground? What sorts of colors do you like? Have you ever fallen off of something? What did you fall off of?"

Students were also to consider safety issues. They had to research government safety guidelines on playground equipment, which, according to Fritz, students found to be rather tedious.

"So that was probably their least favorite part, going through that. They had to do some research…Let's say that they were doing a slide. They had to go through that document and find that certain area about safety with slides, and make notes about that, and consider it while they were doing their design."

While some students improved on existing, tried-and-true playground equipment, others pushed the envelope and invented a new piece of equipment. Says Fritz, "A couple of them are ideas that I have never seen…They drew them out, and you look at it, and you are like, 'Oh, that looks very fun! It's neat.'"

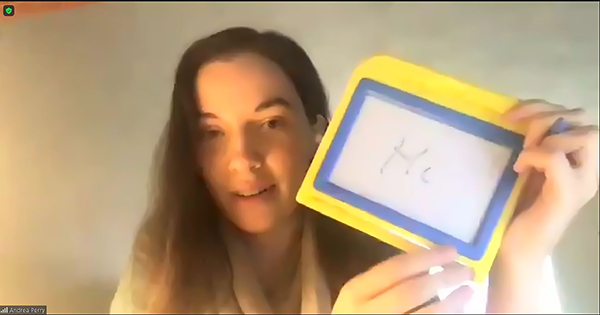

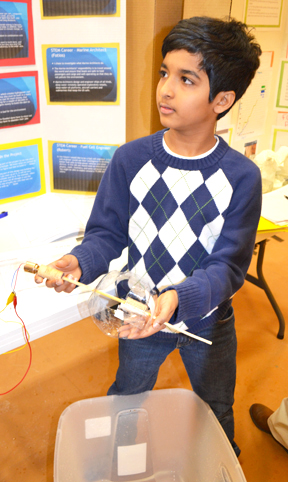

Next Gen sixth grader displays part of his team's hydropower design.

To get their designs down on "paper," students used Autodesk Inventor, a computer-aided design (CAD) software, to create 3D models of their equipment. Drawing on relationships made while participating in Nano-CEMMS professional development, Fritz contacted Illinois' Mechanical Science and Engineering Department for student expertise with the software. To fabricate models of the students' computer designs, he enlisted the aid of Dr. Keng Hsu in Illinois' Ford Manufacturing Lab, which specializes in rapid prototyping.

So what was Hsu's take on the Next Gen projects? When Fritz dropped off the Inventor files to Ford Lab to be processed, Hsu opened them up to see what the kids had done. Fritz reports that a couple of times, Hsu remarked, "Oh, that is pretty cool" or "That is a neat design," which Fritz admits he found gratifying.

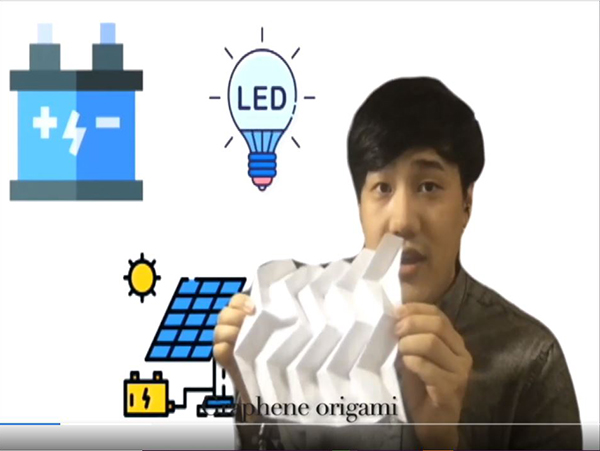

The sixth graders' final project was a renewable energy source, such as solar, biofuel, wind, hydro, etc. After researching how it works, students had to look into other aspects, like: What is its future? Is it viable? How efficient is it? Their goal was to come up with a working prototype, refine it, and make it work. Fritz reports that the Biofuel team actually got a "donation" from a local farm. "So they are trying a little experiment with that one to see which, cow manure, a combination of cow manure with different organic ingredients like bananas, etc., would give them the most gas coming out." Then Fritz proudly indicated a far corner of the room where the experiment's balloons were starting to fill up with gas.

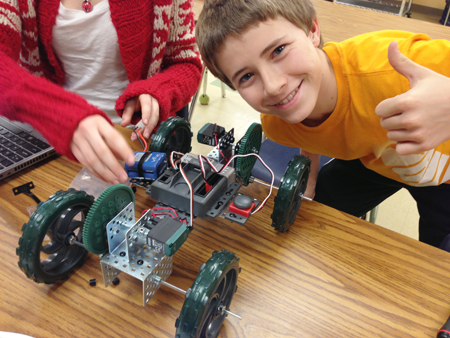

Eighth grader proudly displays robot he helped build during Fritz's Project Lead the Way unit (photo courtesy of Bryant Fritz).

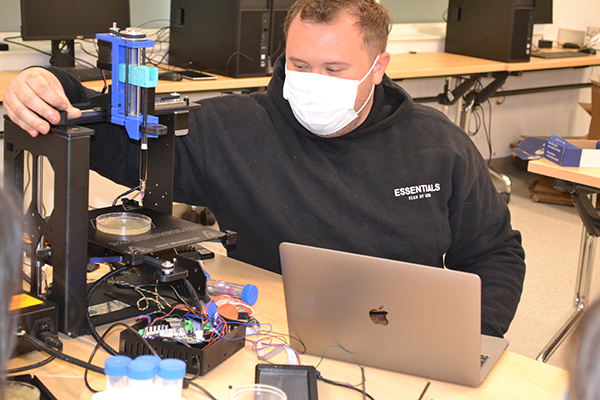

The eighth graders' unit dealt with robotics. After learning some of the principles, such as torque versus speed, how to write code, and sensors, the students used VEX kits to build their projects. One, "Elevator Challenge," was just that: an elevator. Another, "Pick and Place," was a manufacturing arm that could actually pick up an object and move it to a different location. "Tollbooth" had sensors with a red light, (which means "stop"), when the gate was moving up or down, and a green light (indicating the car could go).

According to Fritz, one of the benefits—and challenges—of the projects has been students learning to work in groups. "They didn't choose their groups, number one, so they had to learn how to work with somebody maybe they weren't best of friends with. That's especially stressful when you are working with a dynamic when things aren't going well, and you have to communicate 'Hey this isn't working. What can we do to fix it?' with somebody you are not very familiar with…So I think that's a really great skill for them. And it's something that they've struggled with, and they are getting better with, as it goes on."

But Fritz believes the engineering emphasis has been great for his students.

Students display sensors they built as part of their Project Lead the Way unit (photo courtesy of Bryant Fritz).

"They are really interested in it; they are excited about it, and they like the idea of having this problem and having to come up with multiple ways to solve it, and then decide what is the best way to do it, then go ahead and carry it out. So I think it's gotten lot of kids really excited about engineering."

Does Fritz believe any of his students have what it takes to be engineers? "Definitely. Oh, yeah. They are usually the ones that when they hit a problem, they don't stop. It's almost like it just drives them crazy—like they can't go to their next period without figuring out what they could do to fix it. I think those are the kids that are going to be the really great problem solvers in the future: the ones that are not going to stop fully exhausting all the possibilities that they can come up with. So there've definitely been a couple that come to mind that I'm like, "Whoa, that kid is going to do some really amazing things in the future!"

What part of his job does Fritz find particularly rewarding?: Watching some student's face when "the light bulb goes on." Says Fritz: "I love it. It's fantastic. I definitely know that I chose the right job. As a teacher of science—and now the engineering thing—it's really great to see kids' faces when they see something, they figure out something that was frustrating to them. How rewarding it is for all that hard work to pay off and to be there first-hand when it happens! And maybe I helped them along just a little bit or gave them a hint or something like that. So it's nice. That's the really rewarding part."

And a few years from now, when some of the students who accosted him in the hall come back and tell him, "I still want to be an engineer," Fritz, who knows of a pretty good engineering school up the road, will most likely steer them in that direction.

For further information regarding Next Generation School's partnership with the University of Illinois, see these additional I-STEM articles:

- MechSE Gives Back to the Community;

- Next Generation School Fair: Tomorrow's Scientists & Engineers Meet Today's;

- BTW Kindergarteners Have a Ball Learning About Polymers, Manufacturing.

Story and photographs by Elizabeth Innes, Communications Specialist, I-STEM Education Initiative

More: 6-8 Outreach, Champaign Urbana Community, Next Generation School, Project Lead the Way, 2013

Eighth grader explains the Pick and Place robot she helped design to Illinois' Lucas Osterbur during judging at Next Generation's Science & Engineering Fair.

.jpg)