MechSE Gives Back to the Community

Greg Wilk, MechSE student and president of SEM

February 19, 2012

When Next Generation School science teacher Bryant Fritz needed a little help with a Project Lead the Way design and modeling unit involving computer-aided drafting (CAD) and printing 3D models, he knew just whom to call. He contacted the school’s big brother to the north—the Mechanical Science and Engineering (MechSE) Department on the Engineering campus of the University of Illinois.

It didn't take much coaxing to enlist the help of the MechSE folks. Bob Coverdill, MechSE's Director of Advancement, who thrives on outreach and has previously partnered with the school, quickly introduced Fritz to others in MechSE who could help. Greg Wilk, President of the Society for Engineering Mechanics (SEM), a club for mechanical engineering students on campus, jumped at the chance. Since he had been wanting to see his club branch out to do some volunteering in the community, helping at Next Generation School was perfect for their first gig. Emeritus Professor Jim Phillips couldn't pass up the chance to personally enrich the education of his grandson Reed, who is a seventh grader at the school. And Dr. Keng Hsu, Director of the Ford Manufacturing Lab, loves to show off what the rapid prototyping machines in his lab can do.

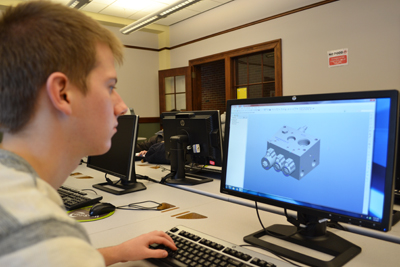

Fritz's Project Lead the Way unit involved students designing playground equipment using industry-grade AutoDesk Inventor software, which allows users to construct 3D images, such as for manufacturing. Their models would then be 3D printed, enabling them to design model playground equipment on a very small scale. Since mechanical engineering students are fluent in CAD programs, this is where Wilk and his SEM cohorts came in. They visited Bryant's class twice a week during the project to act as lab TAs, helping to answer questions, and show the kids how to design models on Inventor.

Wilk's mandate to give back to the community and hopefully steer some youngsters into engineering came about from personal experience: Wilk choose engineering because of the influence of volunteers when he was a youngster. "I think it's really important to give back," he shares. "I remember when I was in middle school and high school, there were people that volunteered in science clubs, and that definitely had a big positive influence on why I became an engineer. So it's important to do."

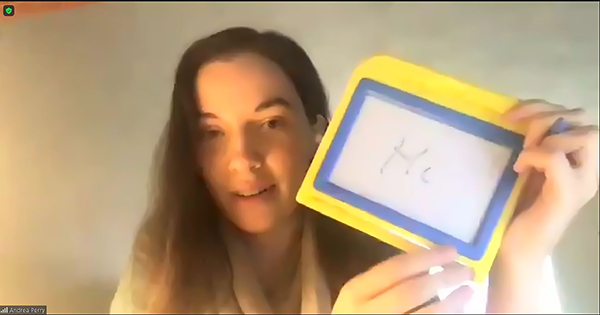

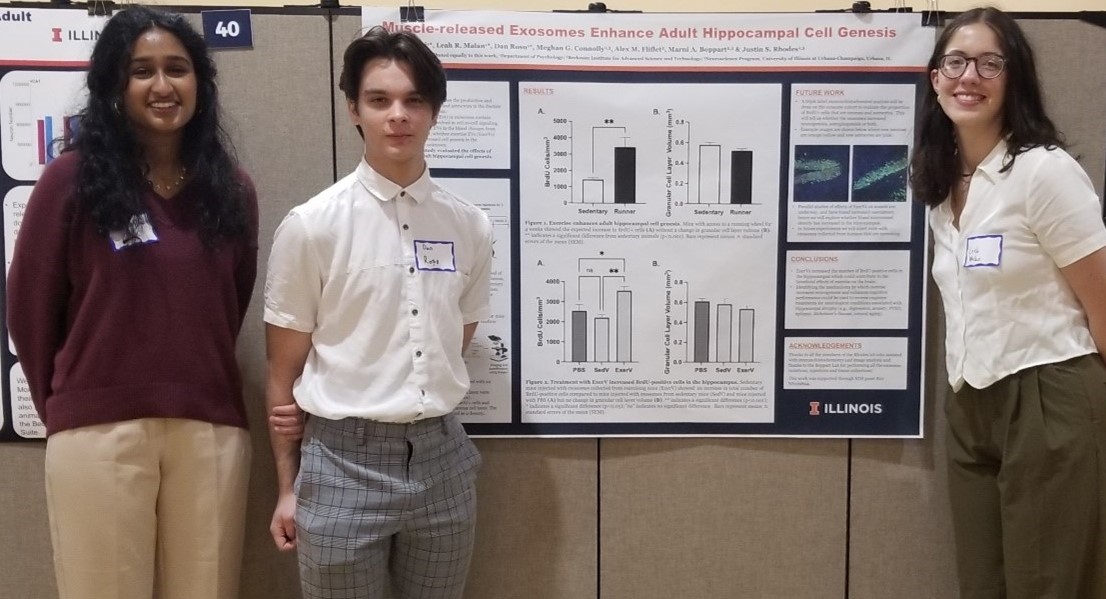

Greg Wilk illustrates a model designed in Inventor.

So, how did the Next Gen kids do? Wilk was quite impressed. "They were doing some pretty complicated geometries with the modeling—lot of spiral shapes. A lot of them had one spiral slides and intertwined spiral slides, and they were able to do it, and make the shapes. So I was very impressed with their ability."

Wilk found it to be very rewarding. "I liked it a lot. I think it was a lot of instant gratification because I'm in school all the time, so I always feel like I am learning, and I don't know anything. But then, you go back to the 7th graders, and now all of a sudden you almost feel like an expert in your area, which was fun. And so they would have a problem or an issue with it, and I would be able to answer it pretty quick. And with this, it's all visual, so you tell them what to do, how to solve it, they go through the steps and solve it, and on the screen instantly appears what they want, and they get a big smile on their face."

Does Wilk think any of the kids he worked with will end up being engineers? "There were a couple that really enjoyed the program," reports Wilk. "They were digging in deep beyond just what the tutorials were. They would go online themselves and look up some different methods and how to do certain things. So yes, I think a decent number of them would go on to become engineers."

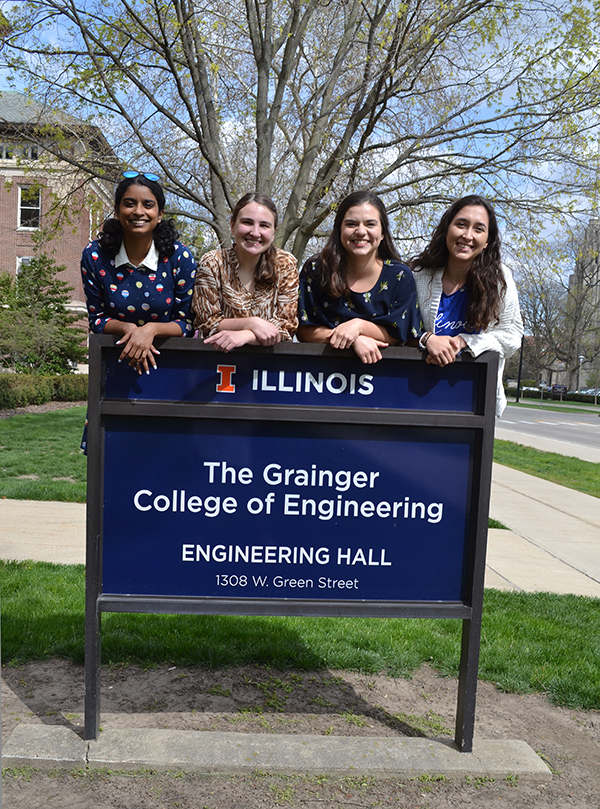

MechSE Professor Jim Phillips and his grandson Reed during a tour of Illinois' Ford Manufacturing Lab

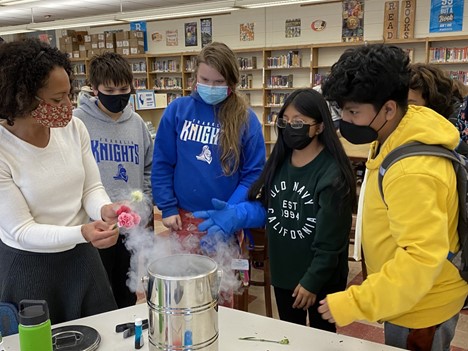

Once Fritz's students finished designing their computer model, the next step was rapid prototyping at the Ford Manufacturing Lab. So Jim Phillips, who admits that having three grandkids at Next Gen was a definite incentive to help with the project, dropped by Fritz's class to give a lecture. He described the three rapid-prototyping machines in the lab and the technologies each uses to create models based on computer-generated 3D drawings: stereo lithography, 3D printing, and selective laser centering, which use either a liquid, solid, or powder to make parts via multiple passes.

While he was at Next Gen, did Phillips notice how the kids were doing do on their software models? "Well, they have no trouble. They're doing fine."

Phillips, who calls himself "old school," goes on to acknowledge that he had never used the program. "They were blowing me out of the water. Because I had actually never learned to use the program myself. I'm from the old school—the old t-square and triangle school—French curves, and Leroy lettering sets, and sharpened 6-H pencils. That is the way I learned. But that was in the year 1960, so things have changed in the last 53 years."

But, proving that you're never too old to learn, Phillips, intrigued by the Inventor software after being exposed to it while at his grandson's school, admits to having downloaded and experimented with it himself. However, he later confessed that while doing the tutorial, on step 5 he somehow lost his model, and had to call his grandson Reed for help.

"I invited my grandson over this past weekend to show me how to use this program…I'm ahead of him on some things, but not on this one. So he was able to show me how to rotate things around."

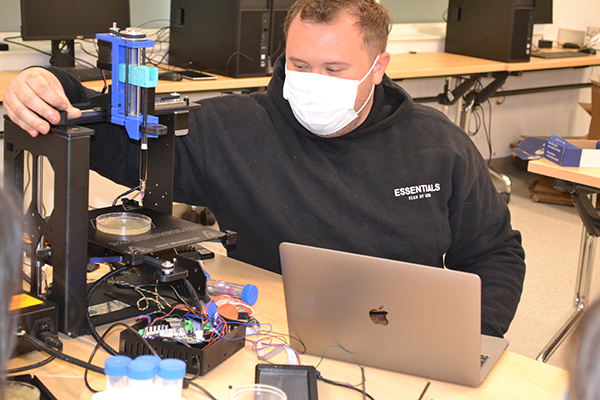

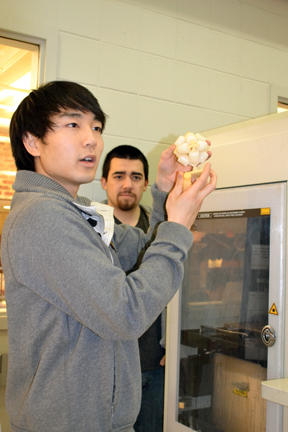

Jim Phillips (left) and Keng Hsu examine a model created in MechSE's Ford Manufacturing Lab.

(Evidently Phillips wasn't the only one to whom the 7th graders showed a thing or two about Inventor. Next Gen teacher Bryant Fritz remembers one of his 7th grade kids using the software, to which a SEM mentor had responded, "Oh, I didn't know that you could do that!" Continuing, the 7th grader responded, "I could just do this," then did an additional procedure, which evoked an excited "Oh, yeah!" from the mentor. "With that program, there are lots of ways to go about designing pieces," adds Fritz, "and I think that [the MechSE students] learned a few things along the way from some of our kids.")

Phillips considers this exposure to CAD software at such a young age to be a real opportunity for the 7th graders. "So the students at Next Generation School are using industrial strength software that is normally introduced here at the University of Illinois at Urbana-Champaign in freshman-level courses. So if a student is in 7th grade and is learning this, he is about 5 years ahead of the curve."

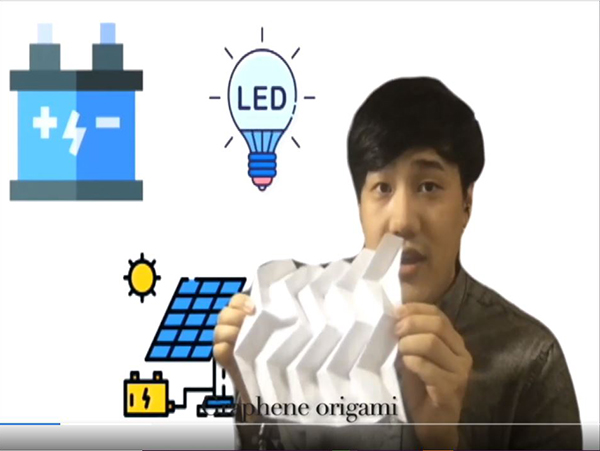

During the Next Generation School tour of the Ford Lab, MechSE grad student Kun Hyuck Lee (left) illustrates the type of model that can be manufactured at the lab, while fellow tour guide Matthew Mayer looks on.

Regarding the quality of the Next Gen program, Phillips is impressed. "In the broad picture, I think students are lucky to go to Next Generation, where they have staff that are keeping on top of the latest techniques in all areas of science and engineering" and goes on to predict, "They will excel in all areas of scientific endeavor."

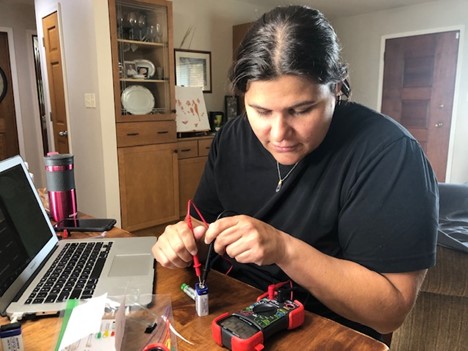

The final step of Fritz's project involved Dr. Keng Hsu, Director of MechSE's Ford Manufacturing Lab. Armed with digital files the students created, Hsu was responsible for determining which of the above rapid prototyping methods was appropriate for each of the projects and manufacturing the models, which took a couple of hours each.

As an added bonus, on February 5, Fritz's students traveled the few miles north to the Illinois campus for a tour of Ford Lab, where they learned more about the rapid prototyping machines and got to examine some of their handiwork. And when Next Generation's Science and Engineering Fair rolled around on February 15, the students were able to proudly display the models they had designed, as part of their exhibits.

For further information regarding Project Lead the Way at Next Generation School, see I-STEM's article: Local Teacher Uses Project Lead the Way to Prepare Next Generation of Engineers

Story and photographs by Elizabeth Innes, Communications Specialist, I-STEM Education Initiative

More: 6-8 Outreach, Champaign Urbana Community, MechSE, Next Generation School, Project Lead the Way, 2013

.jpg)