In the aftermath of a drenching, MechSE Professor Sameh Tawfick, one of the instructors for ME370, celebrates a team's success.

ME370's Drench-Your-Professor Competition Creates a Splash

June 9, 2015

Mechanical Engineering students who took ME370 in Spring 2015 were tasked with designing a couple of mechanisms that would allow them to dunk their professor. Giving students hands-on, practical experience, the course taught them how to work as a team to design something on CAD, then build that mechanism. Part of the process involved overcoming obstacles—students would design, unsuccessfully test, then have to go back to the drawing board and improve their product. And, oh, yes, as added motivation, they got to vie for the chance to pay their professor back for all of those long hours of study by dunking him or her in the dunking booth set up on the Quad.

Of the three sections of ME370 (about 140 students), the top three teams from each section qualified for the event. According to MechSE Ph.D. student Sezer Ozerinc, who helped teach the course, students were provided the motor and water pump, but on their own had to design a couple of mechanisms, one “to combat that rotational motion,” then an additional mechanism that would pump the water into a bucket. The hoped-for scenario was, of course: “that the bucket tips over, and the professor gets wet.”

MechSE Ph.D. student Sezer Ozerinc, who helped teach ME 370, patiently waits for a drenching.

Ozerinc reports that the idea of the Drench Your Professor Contest was to help motivate the students by making it fun, which Ozerinc says they achieved: “It was fun…I think this fun part is making students more happy and more motivated for learning and getting hands-on experience on things like that.”

While the course is fun, Ozerinc says it helps prepare students for real-world engineering:

“Mechanical Engineering is something very applied. If you only go with theory, that would not be sufficient. So here we are both teaching the theory, and at the same time we are giving them the opportunity to come up with some real designs, and they will face practical challenges. As a consequence, they are getting hands-on experience, which they will need in their professional lives when they are designing real things for real purposes.”

And the students definitely encountered challenges and learned how to problem solve. For example, according to Natalie D’Agostino, a MechSE junior: “One of the challenges when we first designed our mechanism, we did acrylic gears, and that plastic just couldn’t withstand the force of the pump. So we realized soon after we tried it with water that it fractured, so then we went with Delrin, which is a much stronger material. It’s really worked for us.”

ME 370 Professor gets a dunking.

MechSE student John Guidone emphasized that for his team, their biggest challenge was the assembly of their dunking mechanism: “The biggest thing was making sure that not only did we design everything correctly like in CAD, but actually assembling was very important, because you had to be very careful that everything was aligned properly. If something was aligned off, there could be a lot of bending or forces that we wouldn’t expect based off the original design.”

Guidone acknowledges that they had a couple of failures in that regard: “We broke a couple shafts, and had a lot of things break early on in testing that we didn’t expect because we just didn’t assemble everything tightly or exactly right…A lot of it was just learning that assembly is very important.”

Guidone says an important aspect of engineering (and life) he learned was perseverance. Like in the old adage, “If at first you don’t succeed...” he and his teammates tried and tried again until they came up with a product they were satisfied with.

A team shows off their design.

MechSE junior Jake Reynolds agrees that overcoming challenges was key to the project: “how to design something that completes a task; I learned the challenges you face and how to overcome them.” And while he admits that it took a lot of time, Reynolds also says, “It was a lot of fun.”

Did the incentive of getting to dunk their professor motivate the students? “Definitely,” Ozerinc says. “I’m pretty sure they were working harder to get into the final competition.”

Sameh Tawfick cringes as a deluge of ice-cold water drenches him.

D’Agostino, who says she enjoyed the whole process, was definitely looking forward to dumping her professor:

“For the overall project,” says D’Agostino, “the hours we put in it, and to see it come from software on a computer, to the final thing, to dumping the professor—I really enjoy that part of engineering entirely. Hopefully he gets wet; we’ll see if it works.”

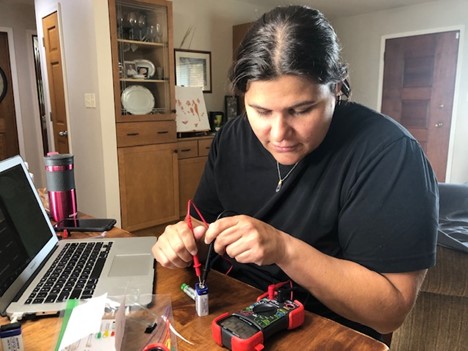

ME370 student Natalie D'Agostino makes adjustments to their mechanism.

Did Guidone find it rewarding to dunk their professor? “Definitely! He’s a great professor, but he had it coming.”

But for him, even more fun than drenching their professor was their sense of achievement: “The thing I was most proud of was just seeing how we made iterations throughout,” admits Guidone. “It was cool to see us drench him I’m sure, but it was really cool to see how we made it early and then iterated until it was just what we wanted.”

I-STEM article on last year's contest: ME 370's Unique "Drench Your Professor" Competition Hones Students' Design Skills

Story and photographs by Elizabeth Innes, Communications Specialist, I-STEM Education Initiative.

More: MechSE, Undergrad, 2015

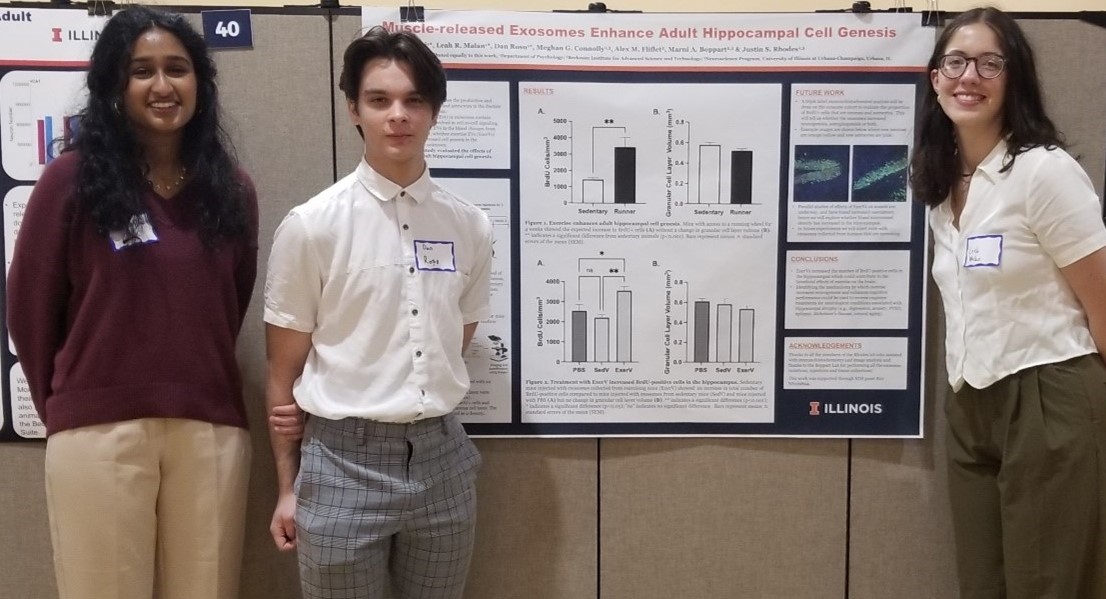

ME 370 students John Guidone, Alex Gray, Steve Wuthrich, and Patrick Klein, display their mechanism which allowed them to successfully drench their Professor, Sam Tawfick, and win the contest.

.jpg)