Uni High Students Get Their Hands On Soft Robotics Courtesy of Holly Golecki

September 18, 2020

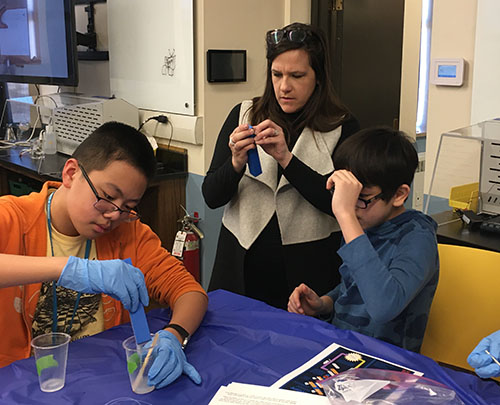

Holly Golecki, (center) watches as Uni High students do a soft robotics hands-on activity. (Image courtesy of Holly Golecki.)

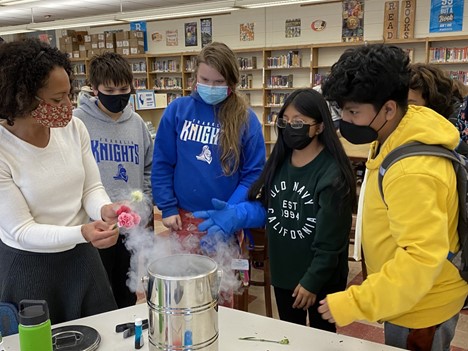

For several days this past February, during University Laboratory High School (Uni High) Agora Days, Uni High teacher David Bergandine and his engineering students set aside their textbooks while Bioengineering Teaching Assistant Professor Holly Golecki led them on a foray into an area she’s passionate about—soft robotics—a brand new area of study that’s creating quite a stir in the biomedical field.

For decades now, Uni High has set aside a week of ordinary classroom instruction in lieu of an alternative schedule—courses proposed by students, faculty, or folks from the campus or the community. So Golecki, who loves introducing high schoolers to her field of study and had already done so at a Pennsylvania school, told herself, “Hey, here's this lab school that's really interested in innovation and bringing unique experiences into the classroom. So try soft robotics!”

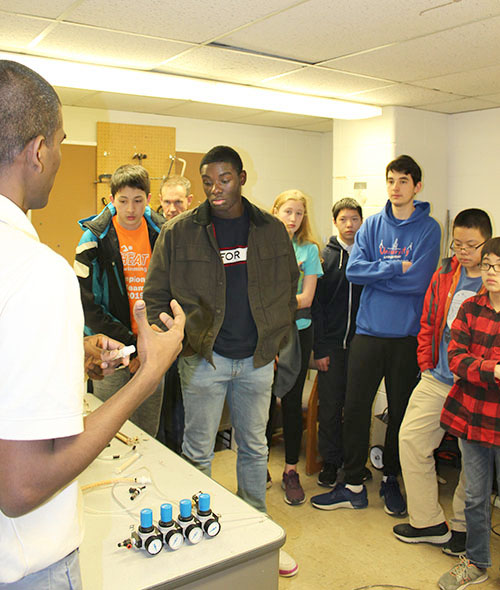

Golecki planned soft robotics activities for four, one-hour periods. The first session was a tour of ISE Professor Girish Krishnan’s Monolithic Systems Lab in the Transportation Building. There students got an overview of soft robotics and saw some things researchers hope to be able to do using soft robots that are difficult with ordinary robotic structures or materials. Regarding the tour’s impact on his students, Bergandine claims: “I think they were really impressed. When we went over to the lab, they were able to see some of the robotics in action and recognize that they're extremely complex mechanisms that require a high level of mathematics that they really didn't quite imagine.”

Uni High students experience soft robotics during a tour ISE Professor Girish Krishnan’s Monolithic Systems Lab. (Image courtesy of Naveen Kumar Uppalapati.)

Regarding some of the things he and his students observed, he describes controlling mechanisms which pull on numerous different wires or strings of different lengths, with various moving parts controlling all those.

“And it gets you to think, ‘How many muscles does it take?’ For instance, you've probably heard before the number of muscles in your face it takes just to smile. So to create some sort of soft robots to do something as simple as smile, you'd have to have many dozens of connections that are behind the scenes to make that happen.”

They also learned other things soft robotics could be used for, like picking fruit, along with discovering some of the challenges, such as training a robot to distinguish if a fruit is ripe, or how to make the robotic hand actually grasp the fruit without crushing it, but handle it in a way that a human might—all really complex ideas. Students also got to see a rudimentary soft robot.

Bergandine and his students were impressed by not only how much researchers working with soft robotics know how to do, but also how hard it might be to get robots to do simple things that might be great applications for these. Plus, he and his students had a chance to brainstorm about what value soft robots might have, and came up with areas like biomedicine or just working in settings with people, such as some sort of robotic assistant for an elderly person with its inherent challenges: to recognize when a person is moving in a certain way and what it might do to assist that person by reaching out or grasping—again without harming the individual. So he and his kids came up with interesting ideas for applications of these things.

Then, for the next three days, back at Uni High, his students got a chance to do several soft robotics activities. For the first two days, they made a wrist brace then a cable-based actuator, respectively, both from the Soft Robotics Toolkit. The final day, they did an activity Golecki herself had developed, along with some help some Haverford School high school students.

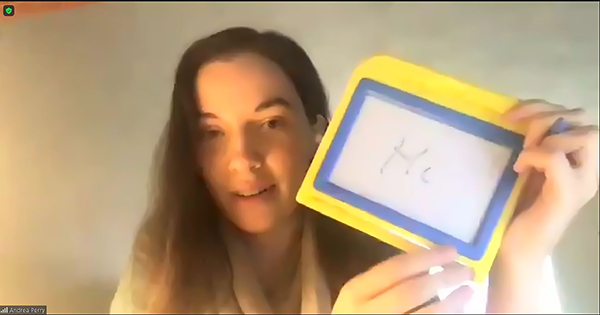

In a recent BioE class, Holly Golecki demonstrates how the Soft Robotics Toolkit wrist brace works.

It’s called a Soluble Insert Actuator, or SIA, which Golecki says can easily be made and is durable. Also, it’s made from silicone, which she claims is commonly accessible; for instance, it can be purchased on Amazon or maybe at Dallas and Company locally, since it’s commonly used to make face masks for theater and costumes, thus it’s safe for use with K–12 students. She shares how the idea for the SIA, including its various iterations, came about.

Golecki’s former students from her 12th grade engineering class at Haverford School in Haverford, Pennsylvania, were really interested in robotics; quite successful in traditional robotics programs, such as Vex Robotics, they had also wanted to experiment in this area. Terming her students as “so into it,” and “very enthusiastic about having more opportunities to practice their robotics skills,” Golecki was teaching them how to make two-part actuators; however, they were having some issues when trying to replicate graduate-level work.

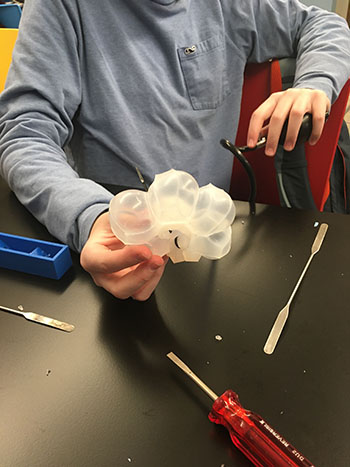

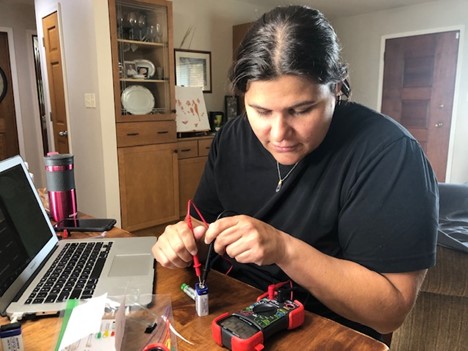

A Uni High student displays the RIA (Removable Insert Actuator) he made. (Image courtesy of Holly Golecki.)

Golecki recalls that one student in particular was very frustrated “because basically they would make a top part and a bottom part, which would then de-laminate from one another. Once it was pressurized,” she recalls, “they would pop apart. Then that student suggested, ‘Hey, I was at a birthday party once where they had styrofoam and poured nail polish remover over it, and the styrofoam dissolved away. So, could we use that to make the internal cavity and then flush it with nail polish remover? So then it's one step, and it doesn't have a top and a bottom. It's just a one-piece mold!’” So that's where the idea for the SIA came from, which Golecki proudly describes as “super cool."

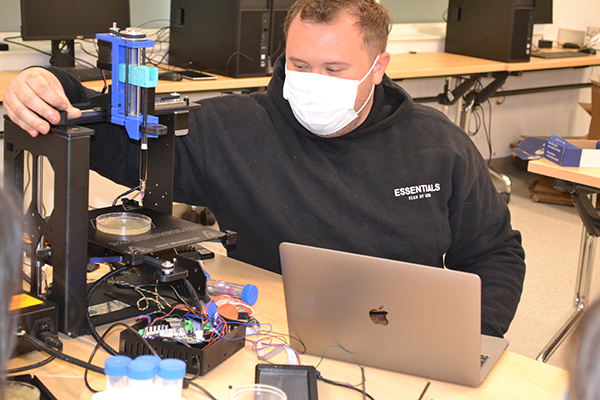

So at first, they were cutting out the internal cavity by hand using styrofoam from Home Depot, then flushing it with acetone. Then another student said, “Hey, I have a 3D printer. We could 3D print PVA, and it's water soluble. So we could print them out of PVA and then flush them out with water!”

Golecki and the Uni High students further refined the process, designing a Removable Insert Actuator (RIA). “We actually just kind of slanted the internal cavity so that instead of having to dissolve it," she reports, "you could just 3D print it out of any material and then just pull it out.”

So is the SIA a groundbreaking innovation—something that could be used in the future for much more advanced research? Golecki says yes. “So one of the ideas with the SIA is that now that you can dissolve the internal cavity, you could make more complex geometries inside it.” Instead of having to pull it out, it could be bending back on itself or other complex geometries that are not possible when you're pulling out the centerpiece. “But if you go in and dissolve it away, it allows for a more unique, complex structure that could potentially lead to different bending geometries of the actuator, and downstream different applications.”

Golecki's grad student, Tianshi Fu, demonstrating soft robotics at Uni High's Agora Days. (Image courtesy of Holly Golecki.)

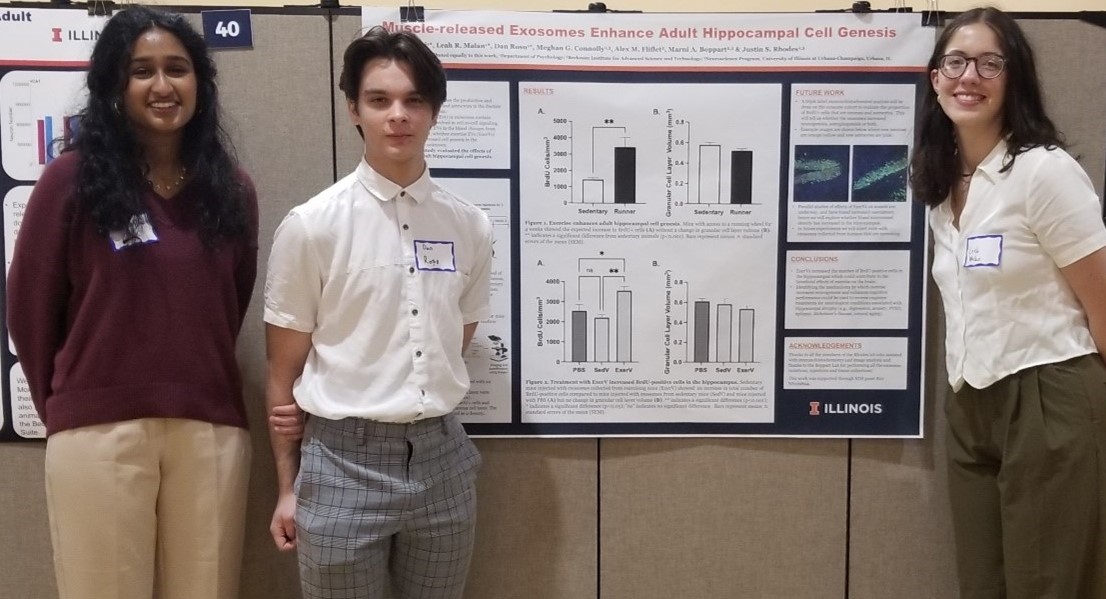

Helping with the Agora Days outreach was Golecki's grad student, Tianshi Fu, who, in addition to exposing the high schoolers to soft robotics and possibly piquing their interest in the field, had another, just as important motivation. He documented the activities as part of his thesis on soft robotics education. "We wanted to find out if high school students can be introduced to basic robotics concepts and perhaps get them interested in the topic," he explains.

Fu believed the outreach had a positive impact on the Uni High students. "While students have some ideas on what robotics in general is," he explains, "most participants never heard of soft robotics and its human-centric applications. We believe this activity opened a new possible avenue for students to explore in the future," then adds that many participants said they would like to learn more about soft robotics or robotics in general after Agora Days.

Like Fu, Bergandine believed few of his students had actual hands-on experience with soft robotics, but believed that if they had experimented with robotics, he felt it was much more likely they had built something that involved hard pieces. “I don't think any of them, if I remember correctly, had experience with soft robotics,” he says. “So it was a great experience for them to the field generally.”

Bergandine appreciated exposing his student to soft robotics, claiming the opportunity was beneficial: “They really got a chance to hands on make some objects and really experience what it's like as a low-level design and manufacturer. But at least they got a sense of what it takes to make these things and what they're doing.”

Were there any particular kids who were really intrigued by soft robotics, to the point that it might shape their future down the road—what they're going to study? “I think the course, overall, was very well received,” he says. “Kids were excited about it. I think we've got students who would be very interested in looking into some bioengineering soft robotics courses or extracurricular experiences. If there was some kind of a formal outreach created for local high school kids, I'd say, definitely, we'd have some kids interested.”

Uni High teacher David Bergandine.

In fact, he’d love to repeat the soft robotics experience with another batch of his students. “If our kids had a chance to do that again, if they could get into those labs and do high school research in those spaces, I'd say they'd be interested.” In fact, he and Golecki talked about possibly beginning a collaborative project between the University folks and Uni High. “Maybe kids could carry on some work here that contributes to research there,” he adds.

He'd also be interested in soft robotics activities his students could do at home, materials they could work with, especially with the COVID-19 restrictions on K-12 education in Illinois. “If something of that type could be created,” he explains, “it would make a difference for lots of kids in lots of places—to have affordable materials that kids could begin to experiment with. And I'm thinking literally it could be as simple as jello.” His idea is that they get some materials, then test their properties to see if they could be somehow interfaced with some sort of driving mechanism. “That's kind of what soft robotics is about,” he adds.

Regarding Golecki’s involvement, Bergandine says: “The kids were very impressed by Professor Golecki, being here, taking the time out to work with us and also bringing some of her staff over. They had lots of material around the room—all kinds of equipment that they brought over and kept the kids really engaged, busy for the full time that they were involved.”

Bergandine particularly appreciated Golecki’s passion for exposing K–12 students to soft robotics: “The enthusiasm that Holly has for her field, for working with young people. And I think that really is going to add a lot to this campus. I think that it's great to bring in a person of her caliber and intensity also willing to work with kids that actually understands kids. That's one of the downfalls of some of our people doing outreaches; they've got great ideas; they've got great motivation; they just don't know how to make it happen. She's, I'd say, very natural.”

One final note: Fu's thesis isn't the only publication about using SIAs and RIAs in K-12 classrooms. Golecki and company (a number of her Haverford high school students, along with Tianshi Fu) recently published an article, "Soluble Polymer Pneumatic Networks and a Single-Pour System for Improved Accessibility and Durability of Soft Robotic Actuators," in the SOFT ROBOTICS journal. It details how the SIAs as well as RIAs are made.)

Story by Elizabeth Innes, Communications Specialist, I-STEM Education Initiative. Photographs by Elizabeth Innes unless noted otherwise.

More: 8-12 Outreach, University Laboratory High School, 2020

For more articles about Holly Golecki, Uni HIgh please see:

- Bioengineering’s Golecki Uses Soft Robotics to Hook Students on Biomedical Engineering…STEM

- Uni High Students Experience Math Research During IGL’s Summer Program

- The Illinois Geometry Lab Partners with Uni High to Expose Students to Research

- Uni High Sophomores Build Infant Incubators Courtesy of POETS-RET-Developed Curriculum

Tianshi Fu (left) helps a Uni High student doing one of the soft robotics hands-on activities during Agora Days. (Image courtesy of Holly Golecki.)

Holly Golecki (second from the left) works with Uni High students doing soft robotics hands-on activities. (Image courtesy of Holly Golecki.)

.jpg)