BTW Kindergarteners Have a Ball Learning About Polymers, Manufacturing

A BTW kindergartener operates a drill press to drill hole in his ping-pong ball mold.

March 11, 2013

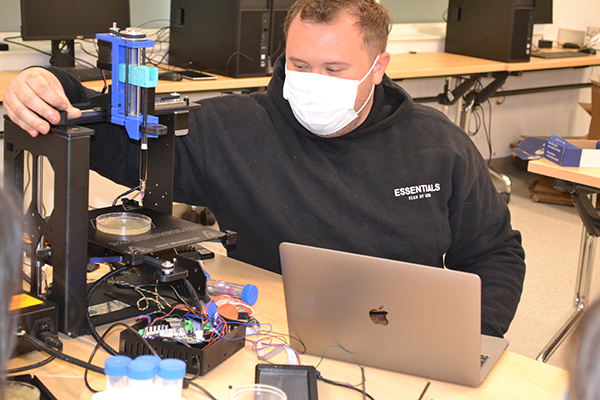

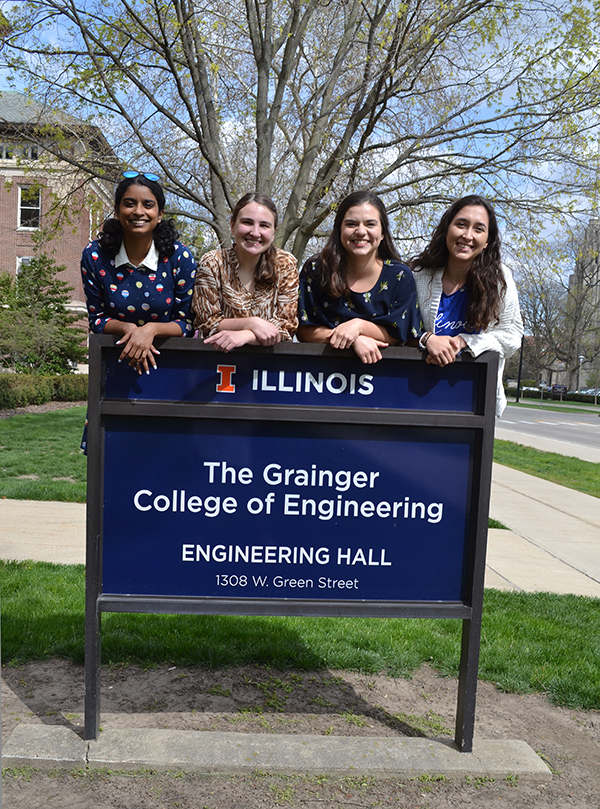

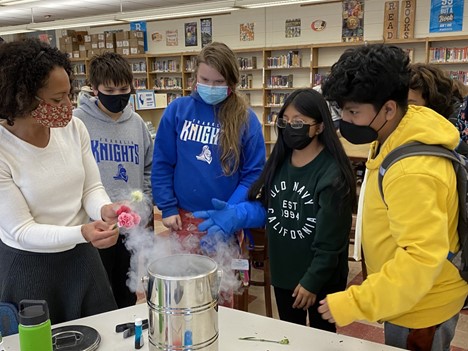

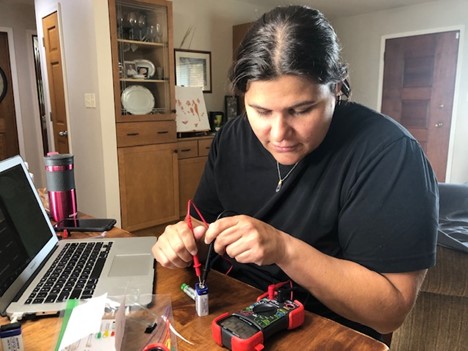

Amidst lots of glitter and armed with rubber gloves and goggles, Booker T. Washington STEM Academy (BTW) kindergarten students recently had the opportunity to make superballs—and were exposed to one type of manufacturing process while doing so. Assisting Nano-CEMM Education Coordinator Joe Muskin, who used his knowledge of nanotechnology and his teaching expertise to guide the youngsters through the process, were about six University pre-service teachers and a team of Next Generation middle school students who sacrificed their day off of school to help mentor the kindergarteners.

During this hands-on project, the kindergarteners learned about using a mold to make a final product. They prepared their mold by drilling a hole in a ping pong ball, mixed up a polymer and cross linker (PDMS), expressed their creativity and individuality by adding some color and/or glitter, de-gassed the polymer, then poured it into the mold.

Not only did the BTW kindergarteners learn some science while having fun, the Next Gen students, who have been learning about the properties of polymers, had the opportunity to teach what they have recently been learning in class. According to Bryant Fritz, Next Generation science teacher, his students "demonstrated the highest level of understanding—the ability to teach others."

Fritz says his students, who studied the chemistry basics last year, are now addressing macromolecules, including plastics, fibers and rubber, and exploring concepts such as bonding types and relative strengths, electronegativity, and functional group trends.

BTW kindergarteners display their polymer-filled ping-pong ball molds which are ready for processing.

With the help of the middle school students and the other volunteers, the BTW kindergarteners used high-level equipment, such as electronic scales, to measure out the perfect ratio; a drill press to drill a hole in their mold for the thermoset process; and a vacuum desiccator to remove gas bubbles produced during the chemical reaction.

According to Fritz, the middle schoolers enjoyed mentoring the kindergarteners: "They had a great time! The kids actually met at our school at 8:30am on a day they had off school due to conferences! I think that is a testament to how much they enjoy science, and I'm glad we're able to offer them these enrichment activities for them to explore. It's amazing to see all of the interpersonal skills that they have while they are teaching others. As you know, the ability to teach someone and relate concepts is the ultimate achievement in learning."

Next Gen middle school student supervises BTW kindergarteners during hands-on project making superballs.

This wasn't the middle schoolers' first exposure to manufacturing. They recently took a trip to Illinois' Ford lab and met Dr. Keng Hsu to learn about the rapid-prototyping process that would be used to manufacture models of designs they had created on computers. Says Fritz, "The Bouncy Ball lab is essentially a manufacturing process and the ball can be seen as a mold for the final product. I think it was neat for our kids and the BTW students to fabricate the ball, understand the science behind it, use math/ratios, utilize a lot of neat technology (desiccators, ovens, scales, drill press)."

Did the older students enjoy teaching the younger ones? "Many students also commented on how the energy of the younger students really made them enjoy the teaching experience, shared Fritz. "Teaching is easy when the audience has such enthusiasm! Judging by the looks on the faces of the kids and the comments on the bus ride home, they genuinely enjoyed the experience. Exploring the love of science and teaching others certainly beats sitting on the couch at home."

Story and photographs by Elizabeth Innes, Communications Specialist, I-STEM Education Initiative

More: Booker T. Washington, Champaign Urbana Community, K-6 Outreach, Next Generation School, 2013

For further information regarding Next Generation School's partnership with the University of Illinois, see I-STEM's articles:

- MechSE Gives Back to the Community

- Local Teacher Uses Project Lead the Way to Prepare Next Generation of Engineers

- Next Generation School Fair: Tomorrow's Scientists & Engineers Meet Today's.

A BTW kindergartener pours polymer into his ping-pong ball mold with the help of a Next Gen middle school student.

.jpg)